|

Clean Room Pass Through Box,Modular Cleanroom,Air Shower For Clean Room Suppliers

| ||||||||||||||||||||||||||||||||||||||||||

|

With the development of computers, microelectronics and information technology, the rapid development of the electronics manufacturing industry has been promoted, and the development of clean room technology has also been promoted. At the same time, higher requirements have been put forward for the design of modular clean rooms. The clean room design of the electronics manufacturing industry is a comprehensive technology.

Only by fully understanding the design characteristics of the dust-free workshop of the electronics manufacturing industry and achieving reasonable design, can the product defect rate of the electronics manufacturing industry be reduced and production efficiency improved.

Features of electronic clean room The cleanliness level is required to be high. The air volume, temperature, humidity, pressure difference, and equipment exhaust are controlled on demand. The illuminance and clean room section wind speed are controlled according to design or specifications. In addition, electronic clean rooms have extremely strict requirements for static electricity.

Among them, the requirements for humidity are strict, because static electricity is easily generated in an excessively dry plant, which can cause damage to the CMOS integration.

Generally speaking, the temperature of the electronic workshop should be controlled at about 22℃, and the relative humidity should be controlled between 50-60% (special clean workshops have relevant temperature and humidity regulations). At this time, static electricity can be effectively eliminated and people feel comfortable.

Chip production workshops, integrated circuit clean rooms and disk manufacturing workshops are important components of clean rooms in the electronics manufacturing industry.

Since electronic products have extremely strict requirements on the indoor air environment and quality during the manufacturing and production process, they mainly control particles and floating dust as the main object. At the same time, strict regulations are made on the temperature and humidity of the environment, the amount of fresh air, and noise.

Factors affecting cleanliness As a huge purification system, the clean room has a large area, but also needs to be divided into complex functional partitions and corresponding buffer supporting rooms, which together constitute a complex air supply and return system.

Therefore, there are many factors that cause the cleanliness of the clean room to be unqualified. mainly includes: (1) Design level and air conditioning layout The design level of the clean room and the air conditioning layout are directly related to the cleanliness level of the clean room. (2) Construction level The overall construction quality of the plant, the installation quality of the air-conditioning system, air supply system, sewage system and other guarantee equipment are closely related to the cleanliness of the clean room. (3) Airflow organization If the airflow organization is unreasonable, the supply airflow cannot fully cover the work area. The unreasonable position of the air supply and return air outlets will produce higher and larger eddy currents, and the air flow deflection angle of the unidirectional flow clean room is too large. If the opening area of the return air grille is unreasonably arranged, the return air speed is too high and the return air is not smooth.

(4) High efficiency filter High-efficiency filter quality problems or installation problems cause the air sent into the clean room to not be effectively filtered, and some dust particles suspended in the air are not filtered, resulting in unqualified clean room cleanliness. (5) Number of air changes Insufficient air changes will cause the polluted air in the clean room to not be quickly discharged from the clean room, and too low air changes will not be able to inhibit the pollution of dust sources. (6) Static pressure difference The unqualified static pressure difference makes the clean room unable to block the external pollutants from entering the clean room. (7) Air shower The air shower room is used as a necessary channel to enter the clean room to reduce pollution problems caused by entering and leaving the clean room. Therefore, its quality is closely related to the cleanliness of the clean room. (8) Equipment placement The unreasonable placement of indoor equipment will affect the air flow in the clean room from top to bottom, from the center to the surroundings, causing air turbulence and preventing pollutants from being effectively discharged from the clean room. (9) New equipment moved in The process of moving in new equipment needs to connect the clean room environment with the outside atmosphere. Therefore, it is necessary to strictly control the moving-in time and the transportation and installation process of the equipment. At the same time, the outer packaging of the equipment must be strictly wiped and cleaned before being moved in. (10) Chemical substances Chemical substances in raw materials and derivatives in the production process will produce certain volatiles, which will affect the cleanliness of the clean room. (11) Cleaning level Incomplete cleaning of the clean room will result in the accumulation of pollutants in the room, resulting in sanitary blind spots. (12) Personnel and material operation During the operation of the clean room, the movement of personnel and materials can easily produce air turbulence around pollution-sensitive activities, which is the main source of pollution for cleanliness. Excessive material flow, excessive number of operators, and improper wearing of clean clothes will all cause excessive dust emission.

[ چهارشنبه 15 مرداد 1399 ] [ چهارشنبه 15 مرداد 1399 ]

[ cleanroomffu ]

Accidents caused by static electricity in clean rooms frequently occur. Therefore, the anti-static ability of clean rooms has become an aspect that cannot be ignored in evaluating its quality. The so-called static electricity is that due to friction and other reasons, the uniform neutral state of the positive (+) and negative (-) charges in the object is destroyed, so that the charge is excessive and the object is in a charged state. Because these charges usually do not flow, so Called static electricity.

Accidents caused by static electricity in the clean room include the following aspects in the clean engineering field that has strict requirements for the indoor environment: 1. Electrostatic shock caused by static electricity can cause people's insecurity and fear, and can cause secondary injury. For example, when a person falls due to an electric shock, he falls and causes injuries. 2. Discharge current caused by electrostatic discharge can cause damage and malfunctions such as semiconductor components. For example, if 50 P-MOS circuits are placed in a plastic bag and shaken several times, 39 NAND gates have been severely broken down, with a failure rate of 78%. This is because semiconductor devices are very sensitive to electrostatic discharge. 3. Electromagnetic waves generated by electrostatic discharge can cause noise and malfunction of electronic instruments and devices. 4. The luminescence of electrostatic discharge can cause damage to the photosensitivity of photographs. 5. The mechanical phenomenon of static electricity can cause the sieve holes to be blocked by dust, the spinning yarn is chaotic, the printing depth is uneven and the product is contaminated. 6. The most dangerous disaster caused by electrostatic discharge is the explosion caused by the fire source well that becomes combustible.

For example, according to foreign literature statistics, among the 86,000 explosive anesthetics used in the operating room, 36 explosions occurred, of which 21 were caused by static electricity.

The occurrence of static electricity accidents mainly lies in the generation and accumulation of static electricity, and the flow of airflow, the friction between airflow and pipes, vents, filters, etc.

The friction between the human body and the clothes, the friction between the clothes, the grinding process, spraying, jetting, washing, stirring, bonding and peeling, all of which may generate static electricity.

In general, the smaller the conductivity of the non-conductor (insulator), the easier it is to be charged because the charge is not easy to flow after generation.

The problem of static electricity is particularly serious in clean rooms because it not only has the aforementioned various process factors that generate static electricity in the clean room.

Moreover, because many materials in the clean room, such as plastic floors, walls, nylon and other work clothes, have high resistivity, they are very easy to generate static electricity and accumulate static electricity. Before the static electricity disaster in the clean room was not taken seriously, these materials Is widely adopted.

With the development of science and technology, the requirements for antistatic, antibacterial and dustproof in the field of cleanroom engineering are getting higher and higher. Sparks caused by static electricity are prone to fire and explosion, and will affect the normal operation of electronic equipment; environmental pollution produces more bacteria, some (such as Staphylococcus aureus) antibiotics have been ineffectively suppressed, and pathogen infection makes people with weak resistance Life is threatened. In response to higher demands, Wiskind is the first to introduce high-efficiency anti-static, anti-bacterial and dust-proof cleanroom panels in the clean field.

The antistatic cleanroom panel uses the color board coating to add special conductive pigments to make the surface of the color board have a resistance of 10-100. Static electricity can be released through this to prevent dust adhesion and easy to remove. At the same time, the pane is resistant to chemicals, The advantages of wear resistance and pollution resistance. A special antibacterial agent is used in the color plate coating of the antibacterial cleanroom panel, which has a non-toxic and semi-permanent antibacterial effect and far-infrared radiation effect.

[ چهارشنبه 15 مرداد 1399 ] [ چهارشنبه 15 مرداد 1399 ]

[ cleanroomffu ]

A warehouse complex with artificial refrigeration and cold insulation, including refrigerating machine rooms, transformer and distribution rooms, etc.

2 storehouseRefers to the main body of the cold storage building and the auxiliary rooms such as staircases, elevators, and hallways serving it.

3 pass through the anteroom Aisles set up for the entry and exit of goods in the cooling room, freezing room, and cold storage room. The room temperature is divided into normal temperature or a specific temperature.

4 cold room The general term for rooms that use artificial refrigeration in cold storage, including cooling time, freezing room, cold storage room, ice room, low-temperature hall, etc.

5 cooling room Room for cooling and processing products

6 freezing room The room where the product is frozen and processed

The cold room used to store cold processed products, among which the cold room used to store cold processed products is called the chilled object cold room; the cold room used to store frozen processed products is called the frozen object cold room

Room for storing ice

9 refrigerating machine room General term for refrigeration machine room and equipment room

10 machine room The room where the refrigeration compressor is installed

11 equipment room Room where cooling auxiliary equipment is installed

12 Cooling equipment load In order to maintain the cold room at a certain temperature, the heat flow value that needs to be removed from the cold room.

13 mechanical load In order to maintain the normal operation of the refrigeration system, the heat flow value taken away by the refrigeration compressor load.

14 Refrigerating system The refrigeration machinery and equipment and related components are connected to each other through pipes to form a closed refrigeration circuit in which the refrigerant circulates to absorb and release heat.

15 Keep to the cooling Technical measures taken to prevent condensation on the outer surface of low-temperature equipment and pipelines to reduce their cold loss

[ سه شنبه 07 مرداد 1399 ] [ سه شنبه 07 مرداد 1399 ]

[ cleanroomffu ]

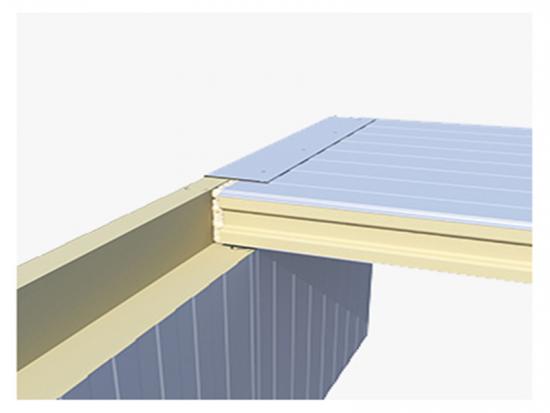

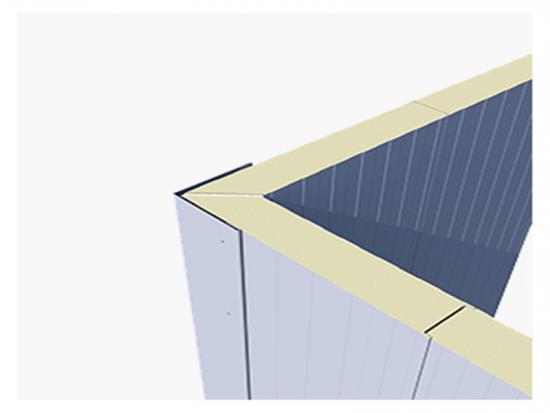

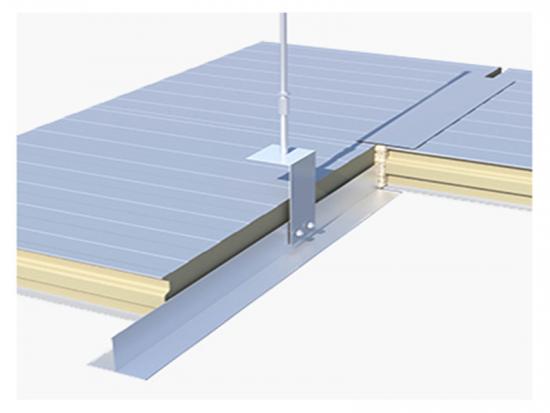

Building a beautiful, beautiful and practical integrated box is a technical job. Are you interested in how to build it? If you are interested, you can come to understand it. Let us follow Wiskind mouduler contain house to understand it! The characteristics of the mouduler contain house are: it can be disassembled and assembled at will, easy to transport, and easy to move. The mouduler contain house is suitable for being located on hillsides, hills, grasslands, deserts, and river banks. No space occupation The mouduler contain house is hygienic and clean, the indoor facilities are complete, the stability of the mouduler contain house is strong and durable, the appearance is elegant, exquisite and elegant, the thermal insulation performance is good, the winter is warm and the summer is cool.

1.Temporary construction(fast installation speed, speed up the start of the project) The mouduler contain house is not like traditional houses that require cement, brick, tile and other building materials. It can be completed directly by using the mouduler contain house module assembly, which saves a lot of construction materials and has higher cost savings. The traditional method is used to build a 100 square meter house The time it takes is 10 times as much as the time spent in the integrated box. Material saving and short construction time are the obvious advantages of mouduler contain houses as temporary houses.

2. Recyclable Because the integrated box is assembled, it can also be disassembled, which means that it can be used repeatedly. Compared with traditional reinforced concrete, it undoubtedly saves secondary costs, and from the perspective of cost, it is also more expensive than traditional The building is cheap. From this, the mouduler contain house can indeed be widely used in construction sites, gatekeepers, newsstands, kiosks, offices, sales offices, classrooms, shops, teahouses, exhibition halls, hospitals, dormitory, canteens, industrial plants, warehouses, parking lots , Simple industrial sheds, single-slope houses, mobile booths, mobile villas, reconstruction of disaster areas, and temporary facilities on site.

The construction knowledge of the mouduler contain house will be shared here, if you have questions or needs in this regard, please contact us to serve you wholeheartedly.

[ سه شنبه 07 مرداد 1399 ] [ سه شنبه 07 مرداد 1399 ]

[ cleanroomffu ]

In the industrial society, standardization and industrialization have become a trend, and the industrialization of houses and modular container houses have been widely discussed in the world. In Europe and Japan,modular container houses have been applied in the middle of the last century. Since the beginning of the new century, China's huge demand for housing and tourism housing, with the research and implementation of housing boxes, modular container houses, and industrialized housing, whether it can alleviate the sensitive housing nerves of the Chinese is still unknown, but at least it is certain What's more, with the development of new materials and new processes, modular box houses or modular container houses will perform a wonderful future in the application fields mentioned above. At least in developed economies, it is no longer a low-end residential term.

Modular container houses are accepted by more and more people for their highly industrialized production methods, efficient on-site installation levels, excellent performance, and healthy home product concepts. In 2020, a new type of coronavirus is coming, and Many people go to the scene to fight against the epidemic during the Spring Festival. modular container houses also participated. Completed two high-standard Vulcan Hill and Thor Mountain Hospitals in just 15 days. The industrialized production characteristics of the modular housing system provide an effective carrier for this revolution. Government departments are also vigorously promoting the development of the construction industry towards industrialization and industrialization. modular container houses are more and more popular for their highly industrialized production methods, efficient field installation levels, excellent performance, and healthy home product concepts. Accepted by people.

The modular house system has complete energy-saving energy storage technology, and the energy-saving effect can reach more than 75%. modular container house sandwich panel walls use environmentally friendly renewable materials, which is conducive to environmental protection. At present, the multi-story residential structure system in China is mainly masonry structure and concrete frame structure. Portland cement material is widely used. Portland material is a non-renewable resource, and it will become a waste that is difficult to recycle and reuse after the building is disintegrated Things, causing great damage to the environment. In addition to the concrete structure of the foundation and core tube, the modular container houses use environmentally friendly and renewable materials, which greatly reduces the use of concrete.

[ پنجشنبه 19 تیر 1399 ] [ پنجشنبه 19 تیر 1399 ]

[ cleanroomffu ]

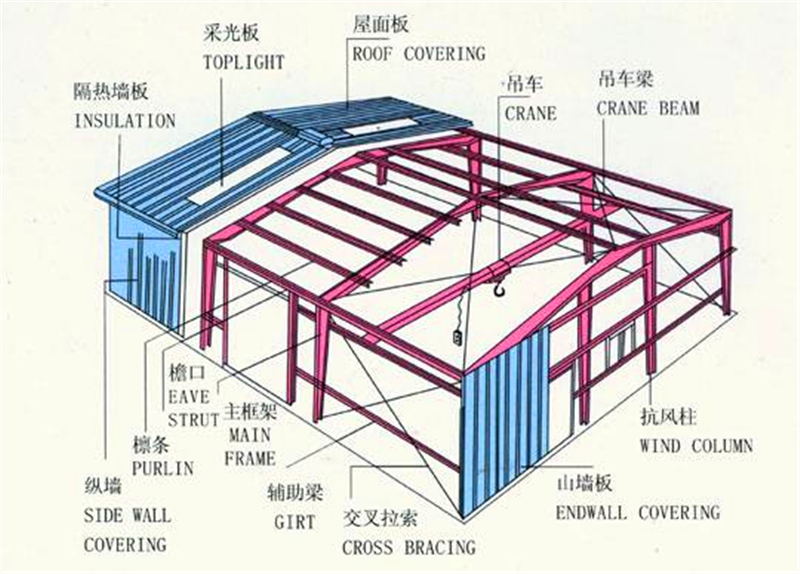

A steel structure is a structure in which a stress member is made of steel. Steel structure housing is valued by all parties for its comprehensive advantages such as light weight, low foundation cost, suitable for weak foundations, easy installation, fast construction, short cycle, fast investment recovery, less pollution to the environment and good seismic performance.

WISKIND is the first grade enterprise of national qualification for steel structure manufacturing, the second grade enterprise enterprise of construction qualification and group member of China steel structure society.

Compared with other structures—brick-concrete structures and concrete structures, steel structures have advantages in terms of function, design, construction, and comprehensive economics. The advantages of using steel structures in residential buildings are mainly reflected in the following aspects:

1.Reasonable arrangement of functional intervals Using the characteristics of high strength of steel, the design can adopt a large room layout, so that the building plane can be reasonably separated, flexible and convenient, and create an open house. The traditional structure (brick-concrete structure, concrete structure) restricts the freedom of space layout due to the material properties. In the past, the booths were usually 3.2 meters, 3.4 meters, and 3.6 meters. If it is too large, it will cause plate thickness, beam height, and column size. The phenomenon of "fat beam and fat column" appears, which not only affects the appearance, but also increases its own weight and increases the cost. Buyers often change the position of the wall by themselves during secondary decoration to increase hidden dangers.

2.Light weight, good seismic performance The building floor of the same building area has a light weight steel structure. According to comparison, the weight of a six-story light steel structure house is only equivalent to that of a four-story brick-concrete structure house. Moreover, steel is ductile and can consume energy brought by earthquakes, so it has good seismic performance and high structural safety.

3.Convenient construction and short construction period The structural components of Yansteel can be factory-manufactured and installed on site. Due to the small amount of work on the site, less pollution to the surrounding environment, at the same time, the degree of construction mechanization is high, and the construction speed is accelerated. According to statistics, the construction period of a steel structure of a building of the same area can be shortened by one third compared with that of a concrete structure, and the supporting material can be saved.

4.The comprehensive cost is low Because of its light weight, reduced basic costs, reduced overall materials, reduced direct costs, short construction periods, and reduced indirect costs, the overall cost is low.

5. Meet the requirements of residential industrialization and sustainable development The steel structure is suitable for large-scale production of factories, and has a high degree of industrialization. It can integrate advanced products such as energy saving, waterproofing, heat insulation, doors and windows into a whole set of applications, integrate design, production, and construction, and improve the level of residential industrialization.

In summary, steel structure is suitable for innovative residential structure system. The steel structure can be designed with a variety of shapes, sizes, and spaces in accordance with different aesthetics and functional requirements. Manufacturers can complete with high precision, high quality, and high speed, so that the building can achieve both beautiful and economical results. With the development of high technology, people's concepts and lifestyles will also be continuously updated and changed, and the requirements for the overall quality of housing will continue to increase. For this reason, residential design must necessarily consider coordination and adaptation to these changing factors , And a new world of flexible design emerges. The steel structure is the most suitable structural system for the flexible design of the house.

[ پنجشنبه 19 تیر 1399 ] [ پنجشنبه 19 تیر 1399 ]

[ cleanroomffu ]

Although the domestic epidemic situation has been curbed to a certain extent, with the start of construction by enterprises in various regions, the production capacity of the original protective masks mainly used for medical and living is stretched again, and the epidemic situation in foreign countries is also in the outbreak stage. Under this circumstance, the gap of masks in the world continues to expand. As China is the largest manufacturer of masks, countries have also hoped to import masks from China. In addition, affected by the epidemic, the habit of hoarding and using masks will continue after the epidemic. Therefore, the global shortage of masks will continue for a long time.

Masks, as a medical device, although the production process is simple, but the production environment must be carried out according to strict standards, that is, the cleanroom level must reach 100,000, the front of the cleanroom must be set up buffer room, dressing room, personnel and materials should be The shower room can only enter after blowing.

Wiskind as a leader in the cleanroom industry, has focused on the production and R & D of high-end cleanrooms for 41 years. Among them, the modular assembled cleanroom is recognized as a new type of high-end cleanroom by domestic and foreign well-known enterprises and institutions. In the wave, the modular cleanroom has become the first choice of many companies. This is the dividend brought by many years of successful case experience and industry reputation. The reason why the modular assembled cleanroom can stand out among many cleanroom manufacturers is thanks to the following Features:

1. Easy and Fast Installation Most of the clean room projects have the problem of delay in construction period. The delay of the construction period not only causes the project schedule, project quality to be out of control, but also triggers disputes between all parties in the project construction. More importantly, it will delay the commissioning of the cleanroom, thereby further harming the economy of the enterprise. interest. Compared with the hysteresis and uncontrollability of the cleanroom project in the construction period control, the modular structure of the assembled clean room and the short construction period can effectively avoid these problems. The on-site installation of the assembled clean room can be completed in 3-5 days. In addition, the factory production cycle and the pressure of the order of the mask clean room eruption can only take about 20 days at most, which fully meets the urgent needs of the mask factory under the epidemic situation.

2. Reusable Because of its modular structure design features, the assembled clean room can be freely expanded or reduced in size and related configuration facilities according to production requirements, and it is convenient and fast to disassemble and install. The main materials can be reused, and the reusable utilization rate can reach 98%. The assembled clean room plays a great role in enterprise relocation and production expansion, saving enterprise costs and improving production efficiency. The majority of the enterprises that switched to mask production are self-produced and self-sold. After the epidemic, the original production line will be restored. The assembled clean room can be dismantled for other purposes and can continue to be used as a mask workshop. Factory choice More items.

3. Reduce Costs Compared with the brick-concrete structure, one of the biggest advantages of the modular clean room is easy maintenance and repair. You only need to replace a single damaged cleanroom panel to repair the walls of the modular clean room without having to redo the entire structure again.

The modular assembly clean room has accumulated a lot of successful experience, Wiskind provides customers not only a single high-quality product, but a complete set of perfect solutions. In addition, we are also a leading supplier in the domestic pharmaceutical industry and hospitals. For overseas markets, we have exported our products to the United States, Russia, Iraq, UAE, Israel, Thailand, Myanmar, Vietnam, Egypt, etc. We are committed to the most influential enterprise in the clean room. If you have a project now, you are welcome to send us an inquiry. We promise to provide the best quality at the best price.

بازدید : 36 [ چهارشنبه 07 خرداد 1399 ] [ چهارشنبه 07 خرداد 1399 ]

[ cleanroomffu ]

A growing number of businesses from different industries can only operate under certain, fine-tuned environmental conditions to maintain product quality and yield. This is where a cleanroom comes in. This special room utilizes a combination of controlled pressure, humidity, and air flow rates, among others. In many cases, they have to maintain an ISO cleanroom at varying levels, examples including ISO 5 through 8.

There are two ways of building a cleanroom: Option 1) you can either erect an extra building next to the main manufacturing plant, which requires significant investment of time and resources along with production downtime; Option 2) or you could construct a modular cleanroom, which takes a fraction of a time to complete and requires considerably less investment than the first option.

Businesses from many industries, especially areas such as pharmaceuticals, biopharmaceuticals, electronics, and other manufacturing environments often go with option 2 instead. Investing in a well constructed modular cleanroom can go a long way in maximizing your production rate and dramatically improving quality of output.

Here are the 5 benefits of constructing modular cleanrooms traditional brick-and-mortar cleanrooms. 1. Quick Turnaround Many organizations seek to minimize delays and hit the ground running at their peak production capabilities. This often means that the time it takes to construct a traditional cleanroom will eat into their production timeline and with it, their profits. The alternative, modular cleanrooms, can be constructed quickly and are easy to set up. They are often constructed from pre-fabricated panels and a sturdy frame, taking only a few hours or days to set up, instead of months that would be otherwise needed for a traditional cleanroom structure.

2. Low Investment Requirements Modular cleanrooms have an efficient design that utilizes ISO standards for construction to reduce the cost of investment while maintaining structural integrity. Cleanrooms constructed this way often require less outdoor air for their humidity and temperature control, greatly reducing the energy costs of keeping the cleanroom environmentally stable.

3. Green Design Modular cleanrooms are highly efficient to operate and provide businesses with the opportunity to utilize green construction techniques. This is important if you want to build a reputation as a brand that cares about the environment and the planet as a whole. Modular cleanrooms often use recycled materials in their construction, which can go a long way in minimizing the burden placed on the earth’s natural resources and cuts down on the amount of waste that is soon going to occupy landfills.

4. Lower Maintenance Costs One of the biggest advantages of modular cleanrooms over brick and mortar structures is the ease of maintenance and repair. You can repair the walls of a modular cleanroom by simply replacing a single damaged panel instead of having to redo the whole structure again. Certain modular cleanroom designs also come with the option of a walkable ceiling, allowing workers to access the cleanroom from above. The idea is to minimize the absorption of moisture in highly humid environments, and therefore maintenance time and costs.

5. Customizable Features

Have specific requirements for the construction of your modular cleanroom? Here at Wiskind, we have an experienced team with the right combination of talent and technical knowledge to help you choose the right cleanroom for your specific industry requirements. Click here to get in touch with us or email us for more details.

بازدید : 29 [ چهارشنبه 07 خرداد 1399 ] [ چهارشنبه 07 خرداد 1399 ]

[ cleanroomffu ]

When the resin drainage ditch is applied to the urban drainage system, if the color depth is different or the exchange capacity of the drainage is rapidly decreasing, the cleaning water is rising rapidly, and the water quality of the effluent is significantly deteriorated, then It can be judged that the resin drain is contaminated during use, and in order to solve the problem of contamination during the use of the product, the following reasons will be known.

1.The pollution caused by organic matterBecause the environment of professional resin drainage ditch is usually harsh, a large number of urban living polluted water sources will contain too much organic matter, and these organic substances can carry negative electricity in the water, becoming an anion,making it become the main substance that contaminate resin drain.Especially among these organic substances, may contain natural humic acid, organic impurities such as micelles, which adhere to the resin and occupy the active gene of the resin.Let it degrade the phenomenon of strong base active groups.Let it degrade the phenomenon of strong base active groups. 2.Suspended matter exceeds the standardSecondly, when the resin drainage ditch is used, if there is too much suspended matter in the contaminated water, it will be tightly wrapped on the liquid film layer on the surface of the resin, so that the ion exchange process of the resin cannot be carried out normally. Let the resin drains have a certain impact during the course of use. 3.Excessive oil in contaminated waterOf course, no matter how powerful the resin drainage ditch is, it must not be able to compete with a large amount of oily substances in the polluted water. These oily substances will form a film on the surface of the resin drainage ditch, and even directly block the micro porous of the resin, hindering the normal operation of the resin drain.

بازدید : 84 [ دوشنبه 02 اردیبهشت 1398 ] [ دوشنبه 02 اردیبهشت 1398 ]

[ cleanroomffu ]

Most of the components of resin concrete drainage ditch are taken from natural minerals such as quartz sand, basalt and granite.These grit as aggregates are screened and proportioned according to different sizes of particle, and mixed with synthetic resin used as cementing material,being produced new concrete with excellent properties. Advantages of the productThe optimized raw material ratio and advanced production process make the resin concrete drainage product show excellent performance.  Weight of the productThe resin concrete drainage ditch has the advantages of high strength and light weight, and the weight of the member with the same pressure resistance level is significantly lower than that of the ordinary concrete, which makes the resin concrete member easier to manually operate during construction, and the cost is lowered. Watertight performanceThe water-inundation depth of the resin concrete drain is 0 mm, showing excellent water tightness and non-hydrophilic. The liquid falling on the surface does not penetrate and stay,decreasing the risk of the frost crack damage of the component. Clean of the surfaceThe surface roughness of the resin concrete drainage ditch is small, and the smooth surface can quickly remove water and debris, which makes cleaning and maintenance work more convenient. Chemical resistanceResin concrete drainage ditch can effectively prevent a variety of aggressive chemical erosion without the need for additional protective layer. It can also be used for a long time under the complicated conditions of sewage composition.

بازدید : 51 [ چهارشنبه 07 فروردین 1398 ] [ چهارشنبه 07 فروردین 1398 ]

[ cleanroomffu ]

|

||||||||||||||||||||||||||||||||||||||||||

| [ فالب وبلاگ : قالب طلایی ] [ Weblog Themes By : goldtem.rozblog.com ] | ||||||||||||||||||||||||||||||||||||||||||