|

Clean Room Pass Through Box,Modular Cleanroom,Air Shower For Clean Room Suppliers

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

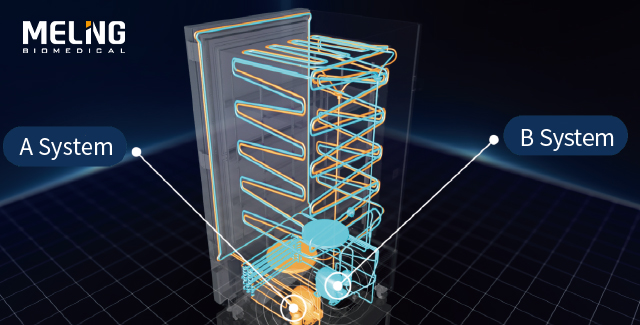

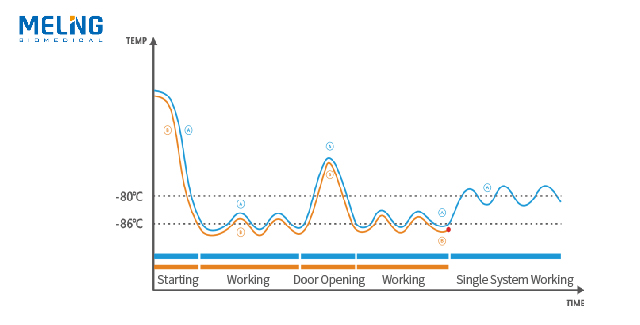

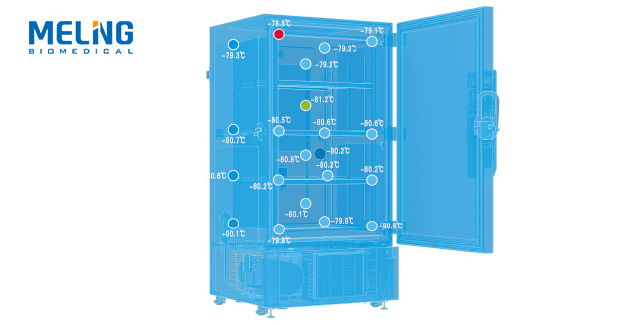

In the biomedical field, there are increasing concerns in the cryogenic storage market for long-term storage of vaccines, cells and bacteria with rapid development of society and economy. Oriented by the ultra low temperature freezers market trend and based on 30 years refrigeration experience, Meling Biomedical will launch -86℃ Twin-drive Variable Frequency ULT Freezer DW-HL780. For the Twin-drive Variable Frequency series , DW-HL780 is equipped with dual independent refrigeration systems of which are completely independent to ensure safety and reliability. For if one refrigeration system fails, the other system can still maintain the freezer box temperature keep at -80°C to offer guaranty for valuable samples.

Frequency conversion technology is adopted to control the compressor speed in real time by adjusting the output frequency to ensure more balanced temperature, thus effectively saving energy.It is applicable to power supply environment with different voltage systems, and it can work normally under various voltage environments such as 110V60Hz, 220V50Hz, 220V60Hz, etc.

It also adopt user-friendly design.Three of Φ25mm access ports, convenient end-user to monitor and test temperature.It has four heavy duty casters for ease of moving and Ergonomic handle, smooth rotating handle track and high-precision pressure relief elastic valve make open and close the door easier. Foam inner door design, built-in VIP insulation board and triple independent silicone sealing strip design make the excellent thermal insulation performance and minimize cold loss once the users access samples.

Since launched in domestic market in 2020, Twin-drive Variable Frequency ULT Freezer DW-HL780 have been in zero-fault running which made it obtained numerous favourable appraisal. The new design and upgrade of Twin-drive Variable Frequency series freezers are what Meling Biomedical has brought to users through continuous self-improvement and technology development. In the future as the pioneer in China’s refrigeration industry, Meling Biomedical will adhere to the philosophy of achieving customers and serving users, continue to pursue innovation-driven development and deliver more advanced scenario solutions and offer advance sales services to encourage more and more customers at home and abroad to choose Chinese goods and services.

[ پنجشنبه 28 اردیبهشت 1402 ] [ پنجشنبه 28 اردیبهشت 1402 ]

[ cleanroomffu ]

The 21st International exhibition for laboratory equipment and chemical reagents Analitika Expo will be held in Crocus Expo, Moscow, Russia from 11 to 14 April 2023. It is a famous analysis and bioanalytical industry exhibition in Eastern Europe and an international trade fair for laboratory instruments and equipment in Russia. It is the market leader in the analytical chemistry industry in Russia and the CIS countries and a central business platform for joint analytical equipment suppliers and experts from different research and development laboratories.

Meling Biomedical belongs to the Top 2 manufacturer in the field of ultra-low temperature storage in Russia. We have been deeply entered to Russian market for many years and have participated in the Analitika exhibition for three consecutive years. We feel pleasant to have this great opportunity to present in Analitika Expo and we will take an active part in exchanging industrial information and up-to-date trend with our peers and partners.

TAGS :

[ پنجشنبه 28 اردیبهشت 1402 ] [ پنجشنبه 28 اردیبهشت 1402 ]

[ cleanroomffu ]

Partners from Mexican National Laboratory of Genomics for Biodiversity (LANGEBIO) Institute has purchased a batch of Meling Biomedical freezers to save biological sample. LANGEBIO , as one of the two of the Irapuato campus of the Center for Research and Advanced Studies, have a unit made up of experts and the necessary equipment to develop large-scale genomic projects to offer scientific services in genome sequencing and analysis to the CINVESTAV community, as well as to other national and international institutions to make contribution to Mexico .

They had purchased Meling Biomedical’s first generation products about seven years ago. They have been in well running and performing their duties to guard sample safety, which has obtained consistent praise from laboratory manager. “It has been so many years and Meling Biomedical’s freezers do well in plasma sample storage.So we choose Meling again when we need more refrigerators.We trust Meling for its ...product quality and service.”praised by users. The freezers LANGEBIO chose this time is Intelligent Touch Screen series.It has RS485 interface compliance to MODEBUS protocol able to transfer data with BMS console.Direct cooling circulation technology with coil evaporator maintains a uniform temperature throughout the chamber and ensure its excellent temperature uniformity.

Our ultra low temperature series adopt unique technology with high-efficiency refrigeration system with the imported high-efficiency compressor and EBM fan are energy-saving and highly efficient. It’s condenser is designed perfectly for temperature stability and refrigeration system reliability since the vacuum insulation panels allow for increased internal capacity with the same footprint as traditionally foamed freezers, as well as it ensures excellent temperature stability. Meling Biomedical is aimed to achieve customers and serve users, we will continue to stand on innovation-oriented development, upgrade to meet advanced international ones through improving the quality of products and services to encourage more domestic and foreign users to choose Chinese goods and services.

[ پنجشنبه 28 اردیبهشت 1402 ] [ پنجشنبه 28 اردیبهشت 1402 ]

[ cleanroomffu ]

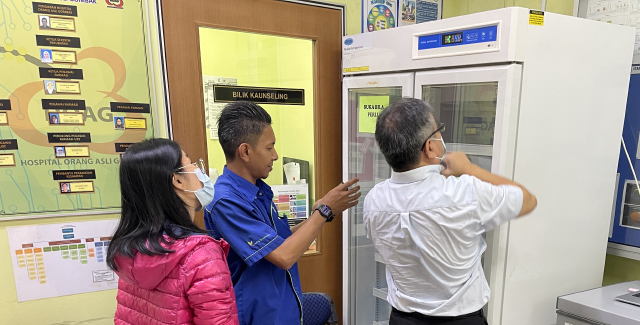

Meling Biomedical has gained more and more approvals in the Malaysian market with leading technology, fast delivery, and considerate sales service. Meling members paid for on-site service to a hospital in Malaysia that had introduced Meling Biomedical pharmacy refrigerators. “The two units have been stably running for four years. It gives our vaccine a safe environment and facilitates us to monitor the temperature in daily use. It is easy for us to operate. In the future, if needed, we are going to choose you as our partner again.” the staff praised.

Meling Biomedical is dedicated to bringing better science and better life to every partner and user. Meling Biomedical adheres to technology improvement and development. The pharmacy refrigerator YC-1015L is equipped with a multi-duct vortex refrigeration system and finned evaporator, which can prevent frost completely and improve temperature uniformity in the cabinet. The high-efficiency air-cooling condenser and finned evaporator of the refrigerator ensure fast refrigeration. This refrigerator comes with multiple audible and visible alarm functions, including high/low-temperature alarm, power failure alarm, low battery alarm, door ajar alarm, high air temperature alarm, and communication failure alarm.

It also has superb technology design. The electrical heating + LOW-E design with double consideration can achieve a better anti-condensation effect for the glass door. And it is designed with removable shelves inside the refrigerator for flexible storage and these shelves remain stable temperatures wherever products are stored, even in a fully loaded chamber. Each shelf is equipped with a label holder, which can record sample information so that users can select the desired samples easily and quickly. Meling Biomedical concentrates on research, development, and innovation, committing to providing safe, stable, and quality products. After years of intensive cultivation in the professional field, we have expanded our market from China to over 80 countries and regions. Meling Biomedical will continue to pursue high-quality products made-in-china to create-for-global.

[ پنجشنبه 28 اردیبهشت 1402 ] [ پنجشنبه 28 اردیبهشت 1402 ]

[ cleanroomffu ]

Rooting in the refrigeration industry for more than 20 years, Meling Biomedical obtained all kinds of patents and developed a range of quality products. Numerous laboratories, scientific research institutes, and hospitals had introduced Meling Biomedical refrigerators and freezers for the leading technology and attentive service. A local hospital in Malaysia is equipped with 14 units of refrigerators, ten of which were made by Meling Biomedical, respectively pharmacy refrigerators, combined refrigerators and freezers, and ultra-low temperature freezers.

According to the user’s feedback, Meling Biomedical refrigerators and freezers performed well. Especially the 2℃~8℃/-10℃~-40℃ Combined Refrigerator and Freezer YCD-FL289 could provide a secure, reliable and stable storage environment for various products within the medical center since installment in the research facility. The customer gave high recognition for Meling refrigerators’ fast cooling function, easy-to-open door, and viewing window. YCD-FL289’s performance exceeded their expectations because YCD-FL289 had two high-efficiency compressors to separately control the upper refrigeration chamber and lower freezing chamber, which could contribute to rapid cooling, energy-saving, and high efficiency.

With a built-in data logger, it could record temperature data for 100,000 sets of data to safeguard the significant sample and facilitate end users. Meling Biomedical combined refrigerator and freezer had equipped with a microprocessor controller to display temperature in 0.1°C increments and multiple audible and visible alarm systems to make sure the temperature inside is stable. The upper and lower compartments had independent padlock which can ensure sample storage security. Besides, the upper chamber had a double glass with low-E, which had the electric heating function to prevent condensation and the lower chamber was solid and had a great insulation function. All exquisite designs and advanced technology were aimed to ensure a reliable and stable storage environment for samples. Meling Biomdical’s freezers were well performed in sample storage. Meling Biomedical is caring for the health and sailing off for life science!

TAGS :

[ پنجشنبه 28 اردیبهشت 1402 ] [ پنجشنبه 28 اردیبهشت 1402 ]

[ cleanroomffu ]

Protecting you from bacteria and viruses via a UV air purifier With the development of technology, UV-C radiation has now become an increasingly popular function that is widely equipped in air purifier for consumers to have the better air quality in their indoor space. Air purifier is a common air treatment device that is used to remove allergens in indoor air such as dust, pet fur, and pollen. Since the rising concerns about bacteria and virus transmission, many consumers have now mainly focused on the capacity of air purifier in eliminating germs when they deiced to choose a proper air purifier for their family. By scientific research, UV light has been known to be one of the effective ways to kill the bacteria and viruses in the atmosphere. In general, UV light can be divided by three types based on their wavelengths such as UV-A, UV-B, UV-C. In respect of air purifier, only UV-C would be more suitable to be applied for germicidal lights. With its wavelength of 100-279nm, artificial UV-C can highly be utilized in medical field to decrease the transmission of bacteria. How does UV air purifier work? The design of UV air purifier is to remained UV radiation within the air purifier. This would be safe for user to avoid the UV radiation as the UV light does not escape from device and air will be disinfected when it passes through the air purifier. When the bacteria and viruses are exposed to UV light, UV-C radiation damages the DNA of bacteria and viruses, which disables these bacteria and viruses from carrying out their normal functions. As the result, they lose their infectivity and die, but this might not be a quick process due to the fact that it has to take up to a few minutes of direct exposure to completely inactivate bacteria and viruses. The concerns of using air purifier with UV function As UV light is cable to damage the DNA, when user is accidently exposed to UV light, their skin and eye might be harm with certain degree. In order to avoid the damage, the following points need to be noted: 1. Ensure that the air purifier cover is securely closed to prevent any opening that exposes the UV light. 2. Ensure that the air purifier is not working when open the cover for filter change or cleaning 3. Ensure that the there is no big damage on cover of air purifier that close UV light. Vork has currently introduced a great number of air purifiers with different function such as UV light, ionizer and WIFI. It is guaranteed to provide best quality product alone with excellent customer service to the consumer for them to enjoy a better life. To learn more about our product, please click here.

[ سه شنبه 02 اسفند 1401 ] [ سه شنبه 02 اسفند 1401 ]

[ cleanroomffu ]

“Innovation technology, Intelligent future”,the 85th China International Medical Equipment Fair(CMEF), ,a medical equipment exhibition, brings together international medical equipment brands to connect with globally licensed medical equipment distributors, resellers, manufacturers, doctors, regulators and government agencies. Meling will attend the exhibition with our Intelligent biological sample bank solution,Lab storage security solution,Intelligent blood safety solution and Smart vaccination solution.

Ours Booth:No.Hall 14,C05 Date:10.13~10.16 2021 Venue:Shenzhen World Exhibition & Convention Center。 Looking forward to meeting you !

[ چهارشنبه 12 آبان 1400 ] [ چهارشنبه 12 آبان 1400 ]

[ cleanroomffu ]

According to the date from the Malaysian Ministry of Health,the number of deaths due to COVID-19 in the country over the past 24 hours has dropped to two digits. So far, The number of fully vaccinated people in Malaysia has reached 52.6%, and the number of people receiving at least one shot has reached 65.4%. The country’s goal is to reach 80% vaccination rate by the end of 2021 to achieve herd immunity. To better implement the vaccination plan, the MOH of Malaysia purchased 227 ice-lined refrigerators from Meling for Sinovac vaccine storage. Last week, Meling successfully delivered its last batch of the refrigerators which will be used in more than 70 hospitals for vaccine storage. Meling 2 ~ 8 ℃ ice-lined refrigerator ,which is specially designed for up to 43 ℃ high ambient temperature zones ,has passed strict PQS test , reached the internationally recognized storage standard. The refrigerator has the first "pre-cooling" technology in the industry, through the "pre-cooling mode", it is able to maximize the cold storage capacity of the product before the power failure when the power failure time is known. And with the 110mm super thick insulation and ice packs ,the holdover time is up to more than 20 hours after power failure.Compared with ordinary medical refrigerators, Meling2 ~ 8 ℃ ice-lined refrigerator can greatly guarantee the safety of vaccines especially for areas with unstable power supply. Besides, the refrigerator has many user-friendly designs.For example,the optional special up and down lift type hanging frame effectively solves the common problem of storage space wasting , make the storage of items more orderly and easier to retrieve and avoid the trouble of moving other items (layer upon layer) when picking and putting.Door automatically close when opening angle is less than 30% make it convenient for people to close the door when holding the vaccines after taking them out . As the earliest national high-tech enterprise in cryogenic field,Meling Biology & Medical pays close attention to the vaccination work around the world, assists the safe storage of vaccines and care for people's health with professional attitude and strong technical strength .

[ چهارشنبه 12 آبان 1400 ] [ چهارشنبه 12 آبان 1400 ]

[ cleanroomffu ]

The World's Largest Ultra-low Temperature Freezer,Have You Ever Know? The largest fresh water lake in the world is Lake Superior The largest hydropower station in the world is Yitaipu Hydropower Station The largest island in the world is Greenland So in the field of ultra-low temperature,Who is the largest Ultra low temperature freezer? This is the one

Yes, that's it!------------- - 86 ℃,the world's largest Android Control System Ultra Low Vaccine Freezer DW-HL1008SA Effective volume 1008L Can store about 770 freezer boxes (2-inch size) About 77,000 frozen storage tubes (2ml) Pleasing appearance and ergonomic design Simple and reasonable color matching, giving you a comfortable visual experience. Sight-level display ,make it easy to check and operate.Rotary door handle for easy opening and closing, universal casters and leveling feet ,make it easy to move and fix. Dependable quality In addition to capacity, the configuration is also excellent. High precision Microprocessor temperature control system 7-inch Android HD display touch screen,dynamically displays parameters in real time Bluetooth connected to WiFi Also have settings and message board function "Dual core targeted refrigeration" and 14 kinds of sound and light alarm systems ensure the safety of stored items. High-performance VIP vacuum insulation material, make superior refrigeration and heat preservation effect. High-efficiency Scop/Embraco compressor + separated evaporator + composite heat exchanger + optimized fractional condensation & separation system + high-efficiency thermal insulation system can save energy and reduce power consumption of the freezer by 40%.

The trusted choice of users all over the world

Billions of samples’ guardian , looking forward to meeting you!

[ چهارشنبه 12 آبان 1400 ] [ چهارشنبه 12 آبان 1400 ]

[ cleanroomffu ]

So far ,39.5% of the world population has received at least one dose of a COVID-19 vaccine.5.29 billion doses have been administered globally, and 41.1 million are now administered each day. At present, the production capacity of vaccine producing countries can fully meet domestic demand. The necessary facilities and equipment for vaccination are almost all in place. But vaccination rates in low-income countries are less than 1.7 per cent. The next step of vaccination work is for vaccine-producing countries to export to low-income countries. This will create a need for supporting equipment in low-income countries,like vaccine refrigerators. Meling 2~8℃ pharmacy refrigerators and -86℃ ultra-low temperature freezers are very good choices. We can provide you with suitable products to meet your requirements whether for vaccine storage or pre-vaccination storage. No matter large volume pharmacy refrigerators, ultra low temperature freezers, or undercounter/benchtop small medical refrigerators ,they are all available.Our pharmacy refrigerators capacity from 55L to1505 liter (three doors) ,and freezers from 1.8L to 1008L. Meling products have been always supporting vaccination efforts around the world. Meling ultra-low temperature freezers for Pfizer vaccine storage in Peru Dual systems, more than 10 kinds of alarms, multiple safeguards for vaccine safety

Meling 2~8℃ pharmacy refrigerators for temporary storage of Pfizer and Moderna vaccine before vaccination in Wanda metropolitan stadium, a vaccine center point of Madrid Real-air cooling, multi-air duct design to ensure temperature uniformity, 7-way sensors multi-directional monitoring of the running status, to ensure the effectiveness of the vaccine

[ چهارشنبه 12 آبان 1400 ] [ چهارشنبه 12 آبان 1400 ]

[ cleanroomffu ]

At present, many countries have developed their own COVID-19 vaccine or have chosen to import vaccines from other countries.Countries around the world have begun to carry out orderly vaccination work.Most vaccines are stored at 2-8℃, some at -25 ℃ or -70℃.However, it should be noted that both vaccines stored at 2-8℃ and lower temperatures need to be taken out of large-volume refrigerators or freezers and temporarily placed in medical refrigerators at 2-8℃ before they are going to be vaccinated. Considering that the number of vaccines temporarily placed on each vaccination table can not be too much, and in order to place and move easily, the small volume undercounter medical/pharmacy refrigerators become the most appropriate choice.And that's why Meling 2-8℃ smart refrigerators YC-55L and YC-75L are so popular in the market. Suitable volume for storage the vaccines at vaccination table, suitable for use as undercounter or benchtop,the refrigerators doesn’t takes up much work space of medical staff and facilitate efficient vaccination work. 10 kinds of alarm,high/low temperature,high ambient temperature,power failure , low battery,sensor failure alarm,door ajar etc. greatly guarantee the vaccine safety.Various running identifications, easy to identify the running status. Rich functions, standard with USB,RS485.Door with heater,maintain no condensation at 32℃ ambient temperature and 80% humidity. 50mm insulation layer,while others are 40-45mm. Meling 2-8℃ smart undercounter refrigerators have been put into use in a large number of vaccination sites in community hospitals, universities, and enterprises.User's approval is the best proof of product quality.

[ چهارشنبه 12 آبان 1400 ] [ چهارشنبه 12 آبان 1400 ]

[ cleanroomffu ]

The Single-dose COVID-19 Vaccine Ad5-nCoV Suitable for Mass Vaccination Following the release of Phase III clinical data of two inactivated vaccines from Sinopharm Group and SINOVAC BIOTECH, the latest data of Ad5-nCoV, an adenovirus vector vaccine jointly developed by the team of Academician Chen Wei of the Academy of Military Sciences and Cansino Bio, was released on February 8.With only one injection, the protection rate can reach 74.8 %.Ad5-nCoV vaccine is the world's first COVID-19 vaccine to enter the clinical research phase which began on March 17 2020.And it is also one of the only two single-dose vaccines in the world that have released the Phase III trial data. Previously,the Johnson & Johnson in the United States announced the results of the its adenovirus vaccine, with the overall protection rate of 66%. The Phase III clinical trial of Ad5-nCoV was first launched in Pakistan on September 22, 2020.At present, clinical trials of the vaccine have been conducted in 78 clinical research centers in five countries on three continents and nearly 50,000 people have been vaccinated.In the results of the Phase III clinical trial conducted in Pakistan, 28 days after a single injection of the vaccine, the vaccine's protective efficacy against severe new coronary pneumonia was 100%, and the overall protective efficacy was 74.8%, without any serious adverse reactions related to the vaccine. Unlike inactivated and mRNA vaccines, this vaccine does not require two injections, and only one injection can be used for immunity, which is very important for the global promotion of vaccination. Although other countries in the world have successively developed COVID-19 vaccines and achieved some results, compared with international demand, it is still a drop in the bucket. Ad5-nCoV is a single-dose vaccine so the procedure for vaccination is simple. It can vaccinate more people in the same period of time, which is beneficial to protect as many people as possible in the shortest time and can achieve rapid mass vaccination. It is reported that another advantage of the vaccine is that it only needs to be stored at 2 to 8 ℃, suitable for transportation and distribution.Mass vaccination requires a large number of refrigerators for vaccine storage. Meling 2-8℃ pharmacy refrigerator perfectly meet the requirements of vaccine storage and preservation. 55L-130L undercounter refrigerators and 315L-1505L capacity refrigerators for your different storage requirements of various scenarios. Precise temperature control and air cooling keep the temperature uniformity within 2℃, which is comparable to a dedicated blood bank refrigerator. More than 10 types of alarms to strictly guarantee the safety and effectiveness of vaccines. If you need to store American vaccines, we also have -86℃, -40℃ ultra-low temp freezers and -25℃ biomedical refrigerators for your choice,we can meet the requirements of refrigerators and freezers covering the full temperature range.

[ جمعه 31 اردیبهشت 1400 ] [ جمعه 31 اردیبهشت 1400 ]

[ cleanroomffu ]

On February 19, 2021, Pfizer Inc. and BioNTech announced the submission of new data to the U.S. FDA demonstrating the stability of their COVID-19 vaccine when stored at -25°C to -15°C (-13°F to 5°F), temperatures more commonly found in pharmaceutical freezers and refrigerators. The data have been submitted to the FDA to support a proposed update to the U.S. Emergency Use Authorization (EUA) Prescribing Information, which would allow for vaccine vials to be stored at these temperatures for a total of two weeks as an alternative or complement to storage in an ultra-low temperature freezer. It is well known now that the Pfizer-BioNTech COVID-19 Vaccine can be stored in an ultra-cold freezer at temperatures between -80ºC and -60ºC (-112ºF to ‑76ºF) for up to 6 months. The vaccines are shipped in a specially-designed thermal container that can be used as temporary storage for a total of up to 30 days by refilling with dry ice every five days. Before mixing with a saline diluent, the vaccine may also be stored for up to five days at standard refrigerator temperature, between 2°C and 8°C (36°C and 46°C ). If approved, the option to store at -25°C to -15°C (-13°F to 5°F) for two weeks would be in addition to this five-day option to store at standard refrigerator temperature. New storage option could offer pharmacies and vaccination centers greater flexibility in managing and maintaining vaccine distribution and supply. The vaccine is administered at room temperature by medical staff. For new storage option,corresponding refrigerator is required. Actually,no matter which storage option you choose, Meling can provide you with suitable freezers and refrigerators. Our product cover the temperature from 8℃ to -164℃. For different storage options of Pfizer-BioNTech COVID-19 Vaccine,you can choose Meling products according to the table below:

[ جمعه 31 اردیبهشت 1400 ] [ جمعه 31 اردیبهشت 1400 ]

[ cleanroomffu ]

Meling 2 ~ 8 ℃ ice-lined refrigerator ,which is specially designed for up to 43 ℃ high ambient temperature zones ,has passed strict PQS test , reached the internationally recognized storage standard,high temperature uniformity and safer storage and obtained the authoritative WHO certification. he refrigerator has very precise temperature control with unique temperature control system and excellent insulation structure.Through the interactive control of the temperature in the box and the temperature of the cold accumulator,it can continuously reach the set temperature progressively, avoiding the problem of temperature undershoot when opening the door or adding new items.The 110mm super thick insulation of the cabinet greatly save energy consumption and greatly guaranteed the temperature uniformity , which is controlled within 1.7℃. It is worth mentioning that ,with with unique system and structure ,it is absolutely the best vaccine refrigerator choice for areas with unstable power supply. The refrigerator has the first "pre-cooling mode"in the industry,through the "pre-cooling mode", it is possible to maximize the cold storage capacity of the product before the power failure when the power failure time is known.And thanks to the 110mm super thick insulation,the holdover time is up to more than 20 hours after power failure.Compared with ordinary medical refrigerators, Meling 2 ~ 8 ℃ ice-lined refrigerator can greatly guarantee the safety of vaccines especially for areas with unstable power supply. Besides, the refrigerator has many user-friendly designs.For example,the handle is combined with the display interface and installed on the top to facilitate observation, door opening, and function selection, avoiding the embarrassment of difficulty to observe the temperature and squatting down to adjust parameters compared to most chest refrigerator. The optional special up and down lift type hanging frame effectively solves the common problem of storage space wasting , make the storage of items more orderly and easier to retrieve and avoid the trouble of moving other items (layer upon layer) when picking and putting.We have two models of this 2~8℃ Ice Lined Refrigerator available for different demand:YC-150EW (150 liters)and YC-275EW(275liters) .

The model YC-275EW won the bid from the Ministry of Health of Malaysia with the number of 85 units. Meling has always been adhering to technological innovation, and we are always ready for your needs.

[ جمعه 31 اردیبهشت 1400 ] [ جمعه 31 اردیبهشت 1400 ]

[ cleanroomffu ]

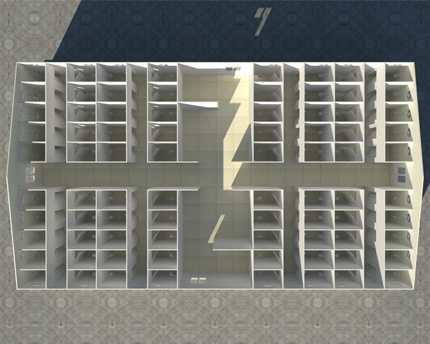

Food hygiene directly affects people's health. Whether it is a processing workshop or a packaging workshop in a food factory, there are very high hygiene standards and requirements. Among them, microbial contamination is the most important factor affecting the quality of food, and it is also the focus of clean engineering in food packaging workshops and processing workshops. Therefore, in the field of food production, it must be clean and safe. According to national production standards, food clean rooms need to meet the 100,000-level air purification standard. The construction of clean workshops in food factories can effectively reduce the deterioration of the products produced, extend the shelf life of food, and improve production efficiency. As the largest manufacturer of cleanroom panels in China, Wiskind puts forward the following precautions for the construction of food cleanroom factories.

1. What is a clean room? Clean room is also called dust-free workshop, clean room, and clean room. It refers to the removal of particles, harmful air, bacteria and other pollutants in the air within a certain space, and the indoor temperature, cleanliness, indoor pressure, Air velocity and air distribution, noise, vibration, lighting, and static electricity are controlled within a certain range of requirements, and a specially designed room is given. No matter how the outside air conditions change, the room can maintain the originally set required performance characteristics such as cleanliness, temperature, humidity, and pressure.

What is a class 100,000 clean room? There are no more than 3.52 million particles with a diameter of ≥0.5μm per cubic meter of air in the workshop. The fewer particles in the air, the less dust and microorganisms, and the cleaner the air. The 100,000-class clean room requires 15-19 air exchanges per hour in the workshop, and the air purification time after complete air exchange does not exceed 40 minutes.

How is the food clean room distributed?

General food clean room can be divided into three areas: non-clean area, quasi-clean area, clean operation area.

Non-clean areas: general storage areas for raw materials, finished products, tools, packaging and finished products transfer areas and other areas with low exposure risk of raw materials and finished products, such as outer packaging room, raw and auxiliary material warehouse, packaging material warehouse, outer packaging workshop, finished product warehouse, etc.

Quasi-clean area: no need for secondary dressing, such as raw material processing, packaging material processing, packaging, buffer room (unpacking room), general production and processing room, non-ready food inner packaging room and other finished product processing but not directly exposed areas.

Clean operation area: Refers to the highest sanitary environment requirements, personnel and environment requirements are high, and must be disinfected and changed before entering, such as: raw materials and finished products exposed processing areas, cold processing rooms for edible foods, cooling rooms for ready-to-eat foods, and waiting for packaging Storage room for instant food, inner packaging room for instant food, etc.

Points to note in clean room construction?

1. The calculation of air exchange rate in the workshop must have sufficient air exchange rate and ensure positive pressure.

2. The temperature and humidity control in the workshop has reached the requirements.

3. The locker room, buffer room, hand washing and disinfection, and other facilities for the staff's secondary change are designed to meet the requirements of the staff.

4. The design of the air shower room.

5. The installation of environmental disinfection facilities in the workshop, such as ultraviolet lamps.

6. The installation of anti-rodent and fly-proof facilities in the workshop, such as fly-killing lights.

7. The location of the air inlet of the workshop should be set up at the air inlet, and there should be a filter system, and should be closed when the machine is shut down.

8. The design of the return air outlet or the return air wall ensures easy cleaning.

9. Treatment of the workshop floor and sewers without stagnant water, and ensure that the sewers are deodorized.

10. The design of the safety door in the workshop to ensure the safety of employees.

[ سه شنبه 05 اسفند 1399 ] [ سه شنبه 05 اسفند 1399 ]

[ cleanroomffu ]

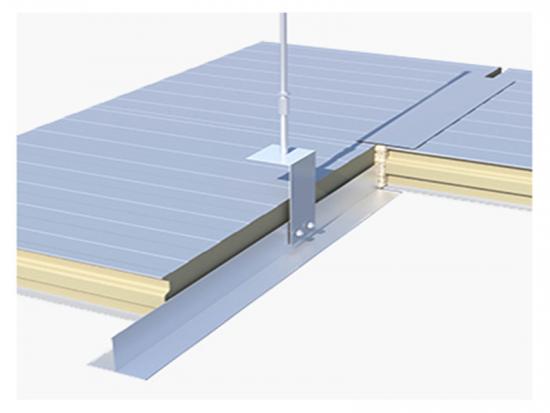

1. What is FFU? FFU is the English abbreviation, its full name is Fan FiIter Units, which means "fan filter unit" in Chinese. To be precise, it is a modularized terminal air supply device with its own power and filtering function. FFU keel is a modular ceiling material (FFU aluminum alloy keel) specially provided for this modularized terminal air supply device, mainly the main material of cleanroom blind ceiling.

The joints are connected by joints, including cross joints, T-shaped joints and corner joints. The entire FFU keel system is reinforced with some threads to form a whole.

2.Unique advantages: 1.The FFU keel is designed according to the characteristics of the clean room. It has a processing tube and is easy to assemble and disassemble, which is convenient for daily maintenance after the clean room is built.

2.The modular design of the ceiling system has large plasticity, which can be factory-produced and cut on site, which greatly reduces construction pollution.

3.The combination of this product is flexible, and a double-layer ceiling structure can be selected, or a single-layer ceiling with only the lower FFU keel can be used.

4.The system has high strength and can walk on the FFU aluminum alloy ceiling keel. It is suitable for local laminar flow systems, FFU systems and air purification systems of different cleanliness levels, and is suitable for electronics, semiconductors, and pharmaceutical industries.

5.The composition of the FFU keel system is also very diverse. You can install the sprinkler at the cross joint, or install some wires for the smoke detector and the lighting lamp. The clean room teardrop lighting can be installed below, and the FFU ceiling can be used with FFU at the same time. Use with fan filter unit.

3. Wiskind Cleanroom Blind Panels Specifications: Sheet specifications: 570mm*570mm, 1170mm*1170mm, 1170mm*570mm Panel material: color steel plate Blind panel thickness: ±13mm Core material: aluminum honeycomb, gypsum Applicable places: electronic workshop, semiconductor, pharmaceutical industry, etc.

[ سه شنبه 05 اسفند 1399 ] [ سه شنبه 05 اسفند 1399 ]

[ cleanroomffu ]

BLOOMAGE BIOTECHNOLOGY is the world's leading high-tech enterprise with hyaluronic acid microbial fermentation production technology as its core. The scale of hyaluronic acid industrialization ranks among the top in the world. Relying on the two major technology platforms of microbial fermentation and cross-linking, the company develops bioactive materials that contribute to human life and health, and has established a business system for the entire industry chain from raw materials to medical end products, functional skin care products, and functional foods. Serviing for global pharmaceutical, cosmetics, food manufacturing companies, medical institutions and end users.

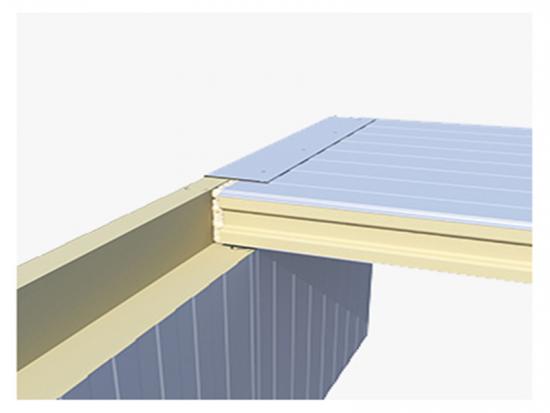

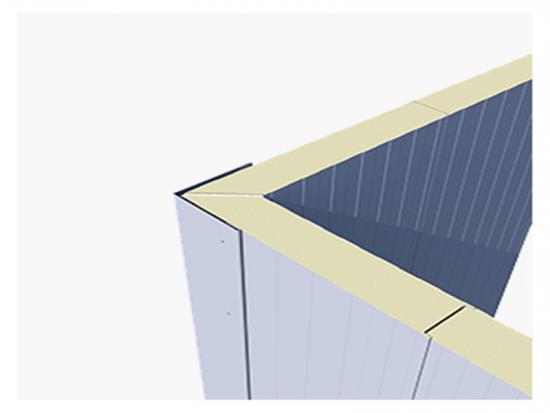

As the world's top hyaluronic acid manufacturer, BLOOMAGE BIOTECHNOLOGY adopts high standards intelligence to build the world's top modern R&D and production base, both in terms of volume and technology. The R&D and production laboratories all use Wiskind cleanroom panels of 15,000 square meters, more than 300 cleanroom color steel doors, cleanroom windows, etc.

The core material of the cleanroom panel is rock wool. Under the premise of meeting the requirements of building thermal insulation, sound insulation and fire prevention, it has reached the goal of high quality, high efficiency, reliability and safety.

The construction workshop is a clean room for cosmetics. As the only one inn China to simultaneously produce sodium hyaluronate raw materials and pharmaceutical excipients by fermentation, It has realized commercial production and passed the US FDA on-site inspection four times. Still at the technical level, BLOOMAGE BIOTECHNOLOGY is the best in the industry.

[ سه شنبه 05 اسفند 1399 ] [ سه شنبه 05 اسفند 1399 ]

[ cleanroomffu ]

In recent years, food safety issues have occurred frequently. An epidemic has made us feel the importance of food safety, especially the nutrition of students, and it has made countless parents full of worries. At present, students’ nutritional meals are uneven, the standards are not uniform, and the workshop design is backward. Looking at various conditions, it is difficult to meet the requirements of the new era for students’ nutritional meals.

In order to ensure risk-free of food safety, it is necessary to uniformly complete the procurement, storage, processing, packaging, sample retention, transportation, cleaning and disinfection of dishes in the central kitchen. Therefore, during the construction process, cleanroom wall panels need to have the advantages of corrosion resistance, high temperature resistance and easy cleaning.

Wiskind provides more than 20,000 square meters of stainless steel cleanroom panels for the Shizhicai Nutritional Catering Center, which fully meets the needs of food cleanroom wall panels. Shizhicai Nutritional Catering Center mainly serves the students of various campuses, employees of large,medium and small enterprises, providing professional nutrition, hygiene, and delicious food service, and providing consumers with healthier and nutritious fast food services.

Secondly, the key point in the construction of food workshops is waterproofing. Since processing utensils need to be cleaned and disinfected and cooking, etc., so they need to be washed frequently. Therefore, when installing cleanroom walll panels on the ground, they must be treated with waterproof floor groove. Wiskind has introduced a new stainless steel waterproof floor groove node to solve the waterproof problem. The new stainless steel waterproof floor groove completely avoids the problem of corrosion and blistering of the panel surface due to washing, which affects the service life of the plant.

Wiskind starting from customer value, focusing on cleanroom enclosure system solutions, further exerting our own advantages, better serving customers, enhancing brand image, and making every effort to maintenance food safety and health.

[ شنبه 02 اسفند 1399 ] [ شنبه 02 اسفند 1399 ]

[ cleanroomffu ]

What is flexural capacity? Flexural strength refers to the ability of a material to resist bending without breaking

Cleanroom wall panels bending resistance experimental: Sample name: double gypsum rock wool cleanroom panel Sample information: rock wool bulk density 100kg/㎥ galvanized keel 0.6mm(T) Baosteel panel 0.5mm(T) Saint-Gobain plaster plate 9.5mm(T) Model specification: 3700mm*1180mm*50mm*1 piece Inspection conclusion: Refer to GB/T23932-2009 "Metallic Surface Insulation Sandwich Panel for Construction" and GB/T29468-2012 "Technical Guidelines for the Application of Sandwich Panels in Cleanroom and Related Controlled Environment Envelopes System". When used in Cleanroom wall panels (L0/250), the flexural capacity is 1.0KN/㎡ The ultimate load is 4.57KN/㎡ Standard for flexural capacity of partition: According to "GB/T 29468-2012", when the deflection of the metal-faced sandwich panel for partition is L0/250 (L0 is the distance between the supports), the deflection of sandwich panels should not be less than 0.5kN/㎡.

Experiments have proved that Wiskind cleanroom wall panels have greater flexural resistance than national standards, and can be adapted to clean rooms such as pharmaceuticals, electronics, and food. The product has excellent performance, can be customized, on-site splicing, convenient and fast installation, and has diversified core materials, including rock wool, PU, EPS, paper honeycomb, aluminum honeycomb, etc. The coating and material of the panel can be selected according to the use environment. Modular cleanroom wall panels can directly open holes and reserve PVC pipes to improve installation efficiency, and the panels can be flush with cleanroom doors and windows, therefore it's beautiful after installation.

Specifications:

Advantages: 1. Core material fire ratings can be viewed. 2. The cleanroom wall panel system is used with aluminum profiles, modular installation, convenient and fast, non-standard can be customized. 3. The factory accepts customization. 4.Diversified core material for different environments, fire protection, insulation, noise reduction, moisture resistance. 5. The factory offers 6 different steel to provide customers with more services. 6. The cleanroom wall panel, strength, flatness, and aesthetics of the cleanroom panel are greatly improved, and the product quality is more stable. 7. The hole reinforcement reservation and the line pipeline box are pre-assembled into the interior of the board in the factory, effectively reducing the secondary pollution during use, especially in the operating room.

Production Technology: 1.Self-developed No.1 Automatic production line for cleanroom wall partition systems. 2. The high-efficiency production line increases production capacity by 6 to 8 times. 3. Accurately measure and control metal plate forming, gluing, core filling, composite molding, and finished palletizing.

[ شنبه 02 اسفند 1399 ] [ شنبه 02 اسفند 1399 ]

[ cleanroomffu ]

In late-stage clinical trials in Brazil, Sinovac Biotech's vaccine has shown 78% effectiveness in fighting COVID-19, and 100% can prevent severe illness.

China Sinovac Biotech cooperated with Butanta Research Institute, Brazil's largest vaccine manufacturer, to conduct Phase III clinical research in Brazil. The agency said on Thursday that among the volunteers vaccinated, there were no severe cases. Although the effectiveness of Sinovac Biotech CoronaVac vaccine is not more than 90% like Moderna, this vaccine is easier to transport and can be stored at normal refrigerator temperature.

In December 2020, Sinovac Biotech announced that it is expected to produce 300 million doses of vaccine in 2020 and increase its production capacity to 600 million doses per year. Sinovac Biotech built a factory in Beijing for the production of COVID-19 vaccine. At present, Sinovac Biotech's vaccine research and development laboratory in China is provided by Wiskind with cleanroom materials, using a total of 15,000 square meters of cleanroom panels.

In view of the particularity of the vaccine laboratory, and taking into account the strength and aesthetic performance of the required cleanroom panels, Wiskind provides magnesium rock wool cleanroom panels, which have the advantages of drug resistance, corrosion resistance, and pollution resistance. It is a pharmaceutical experiment Ideal for room.

As a professional clean room enclosure system service provider, Wiskind has the world’s first cleanroom panels production line with independent knowledge products, which can produce a variety of core materials, and can be customized to meet the needs of different industries. It has been used in pharmaceuticals, food, electronics, and hospitals. Provide professional clean room panels and technical support services for hundreds of customers in many fields.

[ شنبه 02 اسفند 1399 ] [ شنبه 02 اسفند 1399 ]

[ cleanroomffu ]

Clean room door and window gap treatment: Generally speaking, clean room doors and windows have three types of structural gaps. The first category is: the combined splicing and the installation gap between the door and the clean room door; the second category is: the overlap gap between the door and the opening fan; the third category is: the installation gap between the glass or other core boards. The nature is different and their proportions on the clean room doors and windows are also different. Therefore, the airtight measures adopted for the airtightness of clean room doors and windows are not completely the same. Fixed gap treatment: Not only is the number of installed gaps in each clean room relatively small nowadays, but the combination of the door and the opening is relatively hidden after decoration, and it is a fixed gap that is easier to seal. The connection between the rib and the periphery of the hole should be firm, not only for the closed clean room doors and windows, but also the requirements of the general clean room door structure. Due to the large and fierce force of the clean room door, special attention should be paid to the process and the fixing of the clean room door. Whether the fixed points around the opening are firm and stable, but for closed clean room doors and windows, it must also be emphasized that the gap between the chamber and the clean room door or the hole should be tightly filled, and then covered with indoor and outdoor wall decoration layers. The air tightness of this type of gap is basically guaranteed. The second type of fixed gap is the installation gap of glass or other core panel. The treatment of the movable gap: How to overlap the opening fan of the clean room door and the frame material is the key to the design of the clean room door seal. The gap in the lap joint is different from the fixed gap. Because the movable fan needs to be opened, the wood can adopt the "one-and-for-all" sealing measures. Compared with Zhou, the opening fan of the clean room door is larger, and the movable gap occupies a larger proportion of the total structural gap of the clean room door. The number of openings of the clean room door is much more frequent than that of the clean room. The working conditions of the gaps around the door leaf are also more complicated. Take a single flat open clean room door as an example. The two sides along the vertical direction are small. The side with the handle is often subjected to various frictions or collisions during passage, and the side with the hinge is The direction of force applied to the bore due to the rotation of the fan is completely different from the other three sides. We are professional manufacturers of sliding doors clean room、clean room window、aluminium room door etc.

[ چهارشنبه 24 دی 1399 ] [ چهارشنبه 24 دی 1399 ]

[ cleanroomffu ]

Operating room laminar flow air supply ceiling-clean air supply ceiling is the clean operating room, the purifying air supply end of the laminar flow ward, it has the functions of high efficiency filtration, flow sharing and air flow compensation. The rationality of the structure of the laminar flow purifying air supply ceiling directly affects the air supply effect and purification level of the operating room. KLCFILTER laminar flow air supply ceiling is the crystallization of the experience and practice of operating room air supply terminal in the past ten years. This type of terminal has been used in nearly a thousand operating rooms. Its superior performance and unique double-layer DPP flow-sharing network energy The airflow is evenly sent to the working area, and the central airflow compensation device can effectively eliminate the influence of updraft caused by the heating of personnel and equipment on the laminar flow. To Operating room laminar flow air supply ceiling-clean air supply ceiling Working principle: The air supply ceiling consists of a high-efficiency air disinfection and filtration system, a fan power system, a noise reduction system, and an operation control system. When working, the fan inhales ambient air, filters it into clean and sterile air through the air purification and disinfection system, and then delivers clean air to the hospital bed area in the cover in a laminar flow, while maintaining a positive pressure in the cover to prevent dust in the external space Particles and microorganisms enter the hood. With the rapid development of modern medical science and technology, surgical technology has increasingly higher requirements for the clean conditions of the operating room. The 100-level laminar flow operating room is currently the most ideal. However, how to effectively manage the number of air colonies in the laminar flow operating room to meet the air environmental hygiene standards issued by the Ministry of Health, and to meet the clean operating room grade standards, and to reduce it to a minimum. There are few domestic search documents and data. A new topic worth discussing in the management of clean operating room. Laminar flow air supply ceiling adopts air cleaning technology to control microbial pollution in different degrees to achieve the requirements of air cleanliness in the controlled space environment and suitable for various operations; and provide suitable temperature and humidity to create a clean and comfortable operating space surroundings.

Features of laminar flow ceiling: Hundred-level air supply ceiling-Dust-free purification ceiling manufacturer's new second-generation German FFA technology laminar flow purification ceiling, laminar flow ceiling is the purifying air supply end of clean operating room and laminar flow ward, it has both high-efficiency filtration, uniform flow and air flow Compensation effect. The rationality of the structure of the laminar flow ceiling directly affects the air supply effect and purification level of the operating room. Vertical air supply mode, special stainless steel laminar flow air supply ceiling for the operating room: Laminar flow air supply ceilings are developed with reference to international and domestic specifications and technologies. More than ten years of experience in actual hospital use, advanced and reasonable structure, divided into I, II, III operating rooms, the box body is cold plate sprayed, and the lower frame is all stainless steel, which is beautiful and durable. The clean air supply ceiling device is based on the leading leakage barrier technology at home and abroad. The use of this equipment can reasonably distribute the air flow in the clean room and effectively ensure the indoor cleanliness (air supply surface level 100).

[ چهارشنبه 24 دی 1399 ] [ چهارشنبه 24 دی 1399 ]

[ cleanroomffu ]

Hospital operating rooms have very high environmental requirements. How is the air filter installed in the hospital operating room? Today we will introduce the installation principle of the air filter in the hospital operating room. To An air filter in a hospital operating room generally consists of two parts: three air conditioners and two purifiers. The working principle of medical air filters is divided into eight parts: Part 1: Return air section The return air section means that the air volume sent by the exhaust fan reaches the specified air volume, and the recovery system of the medical air filter can send out air. Part 2: Primary filtration Primary filtration is the first filtration procedure performed by non-wind. In this step, we need to replace or clean the equipment for a certain period of time. Part 3: Heating process The heating process is generally an electric heating process used for heating in winter. Part 4: The humidification stage of the medical air filter The humidification stage is mainly to humidify the blower unit through a humidifier, and then reach the temperature for people's affairs. Part 5: Secondary Filtration This is the final filtration stage of the air filter in the hospital operating room. This stage is the final pass to ensure air quality. The air is filtered once, then humidified, and finally filtered again. This ensures the purity of the air and can achieve the medical air filtration effect. Then the filtered air is output.

[ چهارشنبه 24 دی 1399 ] [ چهارشنبه 24 دی 1399 ]

[ cleanroomffu ]

Disinfectants and electronic sterilization devices are necessary daily cleaning items in every family. Especially in the season of a high incidence of influenza and other infectious diseases, the frequency of use of disinfection products will increase significantly. Home UV sterilizers are the most common electronic sterilization devices in modern homes, and because of this year's special circumstances, many new types of UV sterilization devices are being accepted by consumers faster, including home UVC Air sterilizers, UV cutting board sterilizer, etc. So what are the advantages of UV sterilization? Why has it become the preferred method of disinfection?

Effective Against More Germs UV sterilization is a physical sterilization method that directly acts on the genetic material in biological cells. It destroys DNA and RNA to achieve the purpose of killing bacteria and viruses. Therefore, except for a few rare super bacteria, UV sterilization can effectively kill most bacteria and viruses. For the common germs in the home environments, efficient UVC germicidal lights are enough to meet cleaning needs

Fast & Efficient UV rays are very efficient at destroying DNA and RNA. UVC rays of sufficient intensity can even kill bacteria within 1 second. So UV sterilization is very fast, but the sterilization time preset in different UV sterilization device is usually different because of different cleaning needs. For example, a LED UV sterilizer boxthat for cleaning daily small items just needs 5 minutes to achieve the required sterilization rate, and a high-power UV sterilizer used for sterilizing the medical device usually rules the sterilization time as 30 to 60 minutes.

Non-contact, No chemical residue UV sterilization is carried out by light irradiation, and the cleaning work can be completed without touching the objects, which is very sanitary and convenient for the operator. And because of the characteristics of light, it will not leave any chemical by-products on the object after sterilization. So, UV sterilization is more safe and friendly to both the environment and users.

Energy Saving UV sterilizers are representative of low energy consumption in electronic disinfection equipment. The daily power consumption of some small UV light air purifieris even less than 0.2 kwh. At present, UVC LEDs, which are more energy-efficient and efficient than traditional fluorescent tubes, have been widely used in more products. It is believed that many UV sterilizers will have better energy-saving performance in the near future.

Low Cost The UV sterilizers are the disinfection equipment with a mature technology that has been used for many years. Most of the UV sterilizers just need simple maintenance and their service life can reach thousands to tens of thousands of hours. This is a cost-effective way of sterilization and cleaning method for most families.

[ پنجشنبه 20 آذر 1399 ] [ پنجشنبه 20 آذر 1399 ]

[ cleanroomffu ]

If we can turn container into homes, then surely we can turn shipping containers into one of our homes’ greatest accessories — pools. One company is doing just that-CBOX, who is a design company specializing in transforming containers into houses, and recently it has launched a project to transform containers into swimming pools. The swimming pool has a built-in hot water system that can be raised by 10 degrees Celsius per hour, and the swimming pool can be divided into hot and cold water areas through a dedicated dividing plate to experience different water temperatures. Compared with traditional swimming pools that need to be dug, the installation method ofswimpoolsis much more flexible and does not have too high requirements on the soil. If you put it directly on the ground, you can also enjoy the scenery outside through the "window".

Shipping containers are naturally durable and structurally sound,Repurposing a shipping container cuts down the carbon footprint and turns something that may have not been useful into what we think is a lifestyle changing, modern asset. Modpools are just 50 percent of the cost of conventional in-ground pools, and come with a hot tub and pool area that can be separated in the cold months. That means you can decide which portion to heat, and enjoy the separate benefits of both a pool and a hot tub, all for one comprehensive price.

shipping container pools would be easy to install ? A pools ship completely ready to use with all the pool equipment built in. With some light ground prep, power and gas access, you can simply plug and play。which features a window on its side, can be installed where traditional in-ground pools can’t be. Many people have ground that is too hard because of rock or, alternatively, have ground that is too soft because of high water levels. We can be placed above ground with decks built around, partial in-ground behind retaining walls or completely in-ground. We find many of our customers want a pool but are unable to have a traditional pool installed.

And because it’s easy to install, it’s also easy to move — that means no more leaving your pool behind when you move. This is a vast departure from a traditional pool, and makes our pools a smart lifestyle and financial choice.

[ دوشنبه 17 شهریور 1399 ] [ دوشنبه 17 شهریور 1399 ]

[ cleanroomffu ]

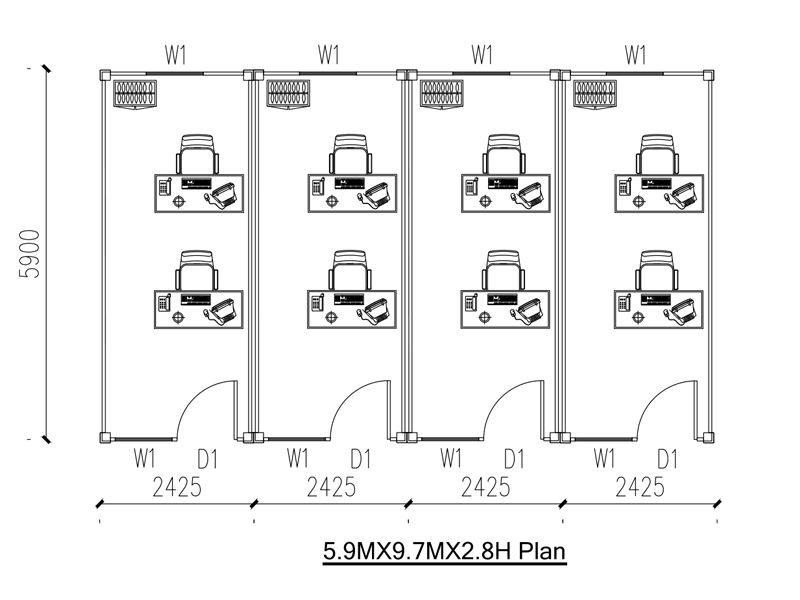

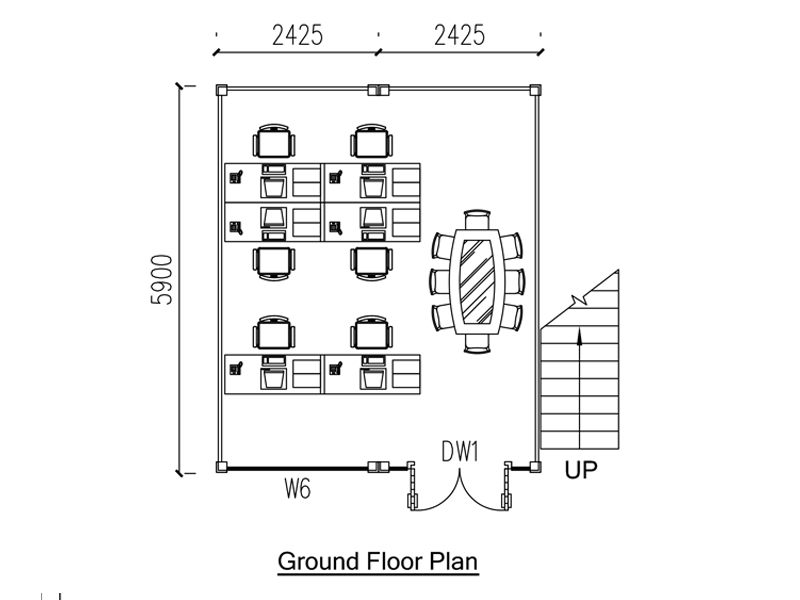

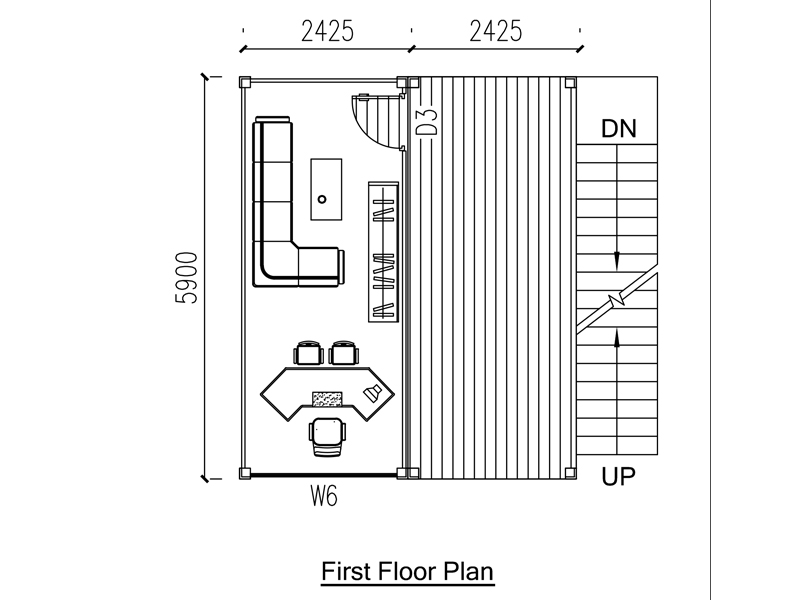

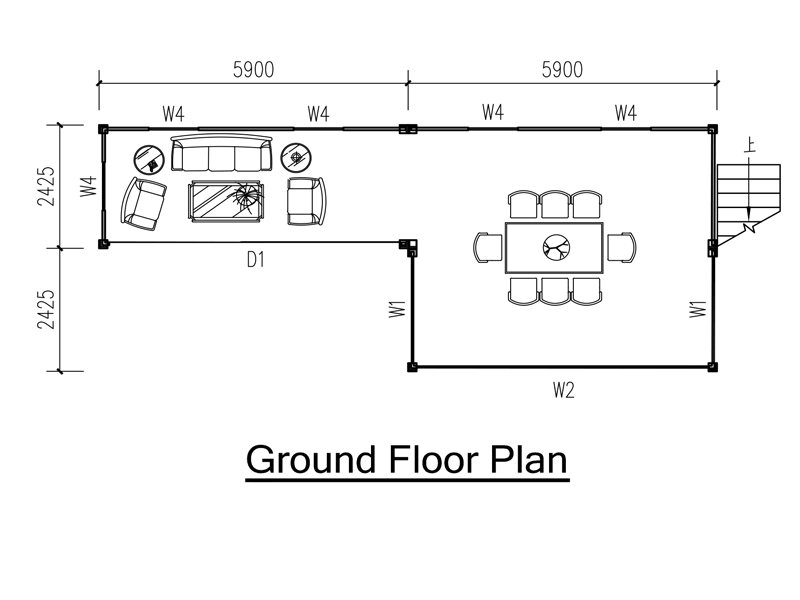

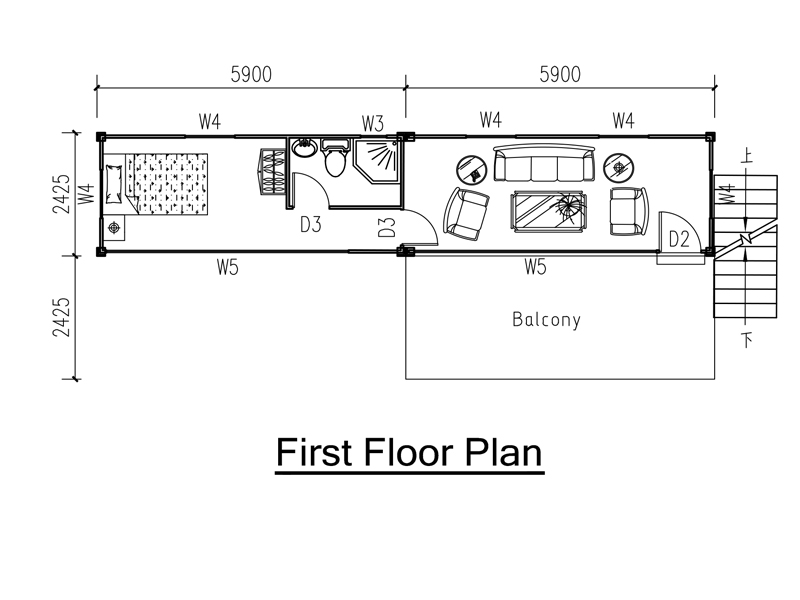

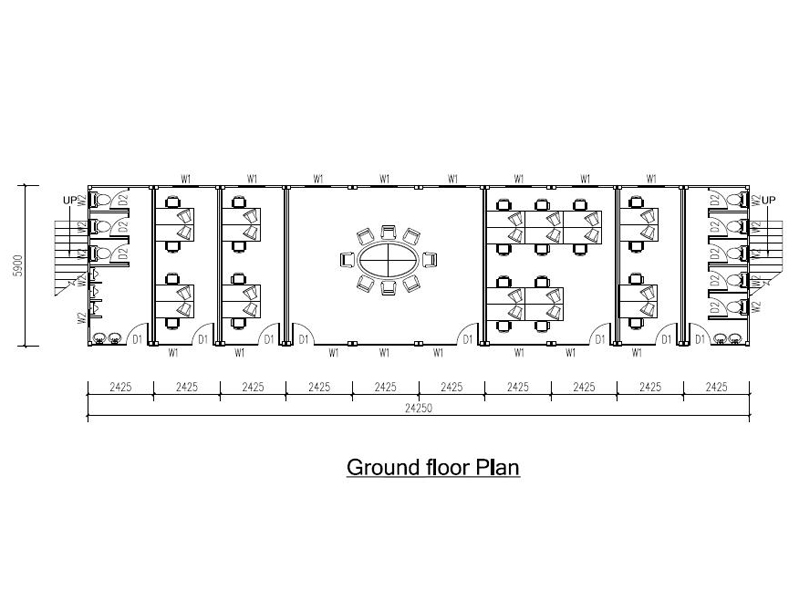

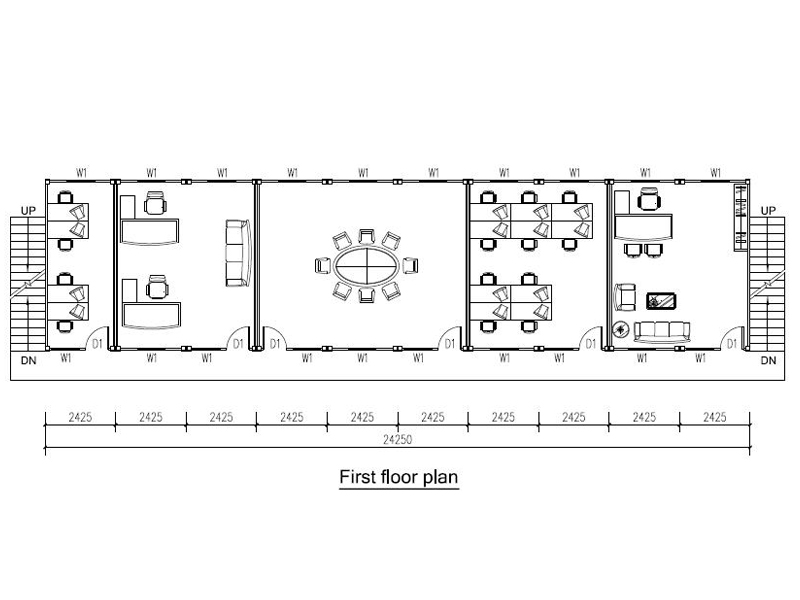

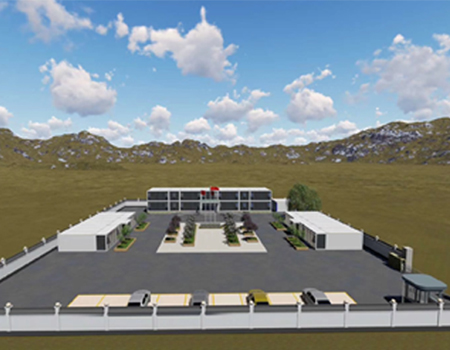

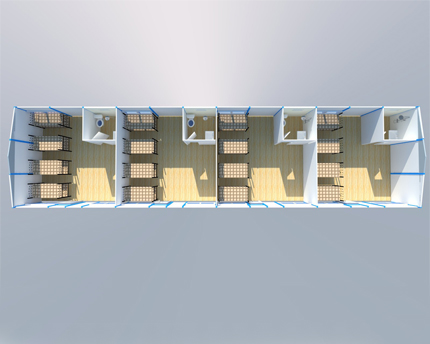

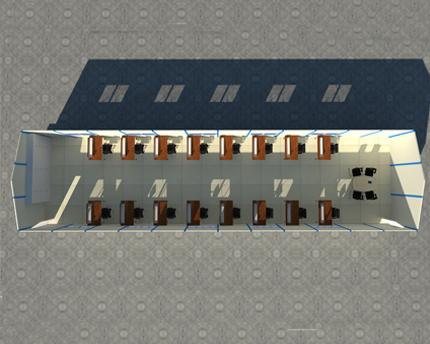

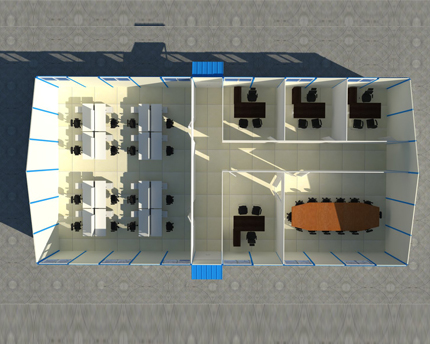

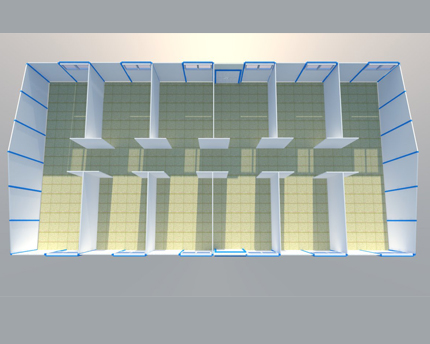

CONTAINER OFFICE These prefab office buildings are assemble by the portable flat pack container house, which characteristic for the completed roof and floor design just need install the wall, window and door in local. Fast installation, 4 people 1 hour can assemble 1*20ft container house. What's more, the container frame is strong enough for 1-3 floor design. The design is flexible, several units can combined.

Type E: Container Office with Staff dormitory camp

We can provide completed Container camp design solution for you, inside have container office, container dormitory, canteen, bathroom, storage, security room etc...

بازدید : 46 [ پنجشنبه 30 مرداد 1399 ] [ پنجشنبه 30 مرداد 1399 ]

[ cleanroomffu ]

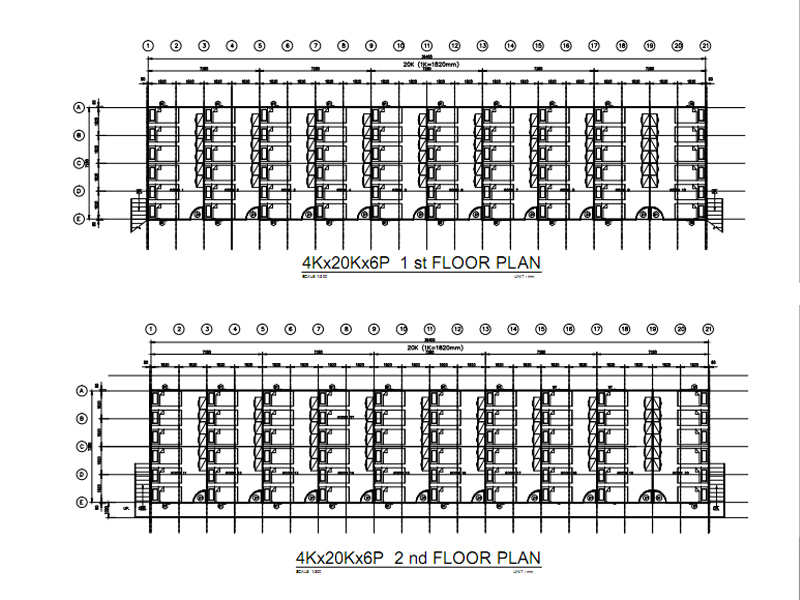

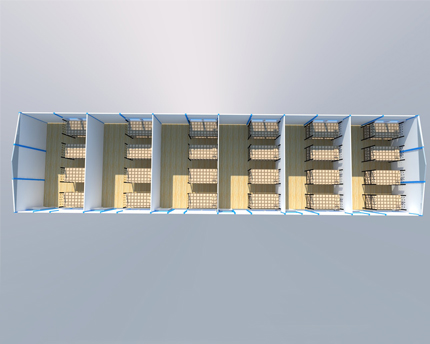

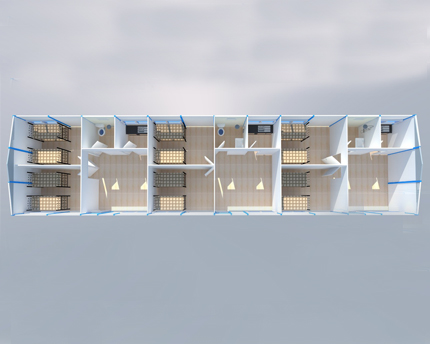

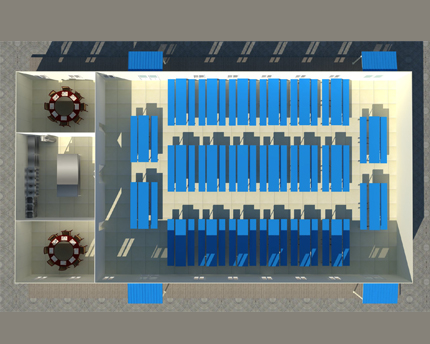

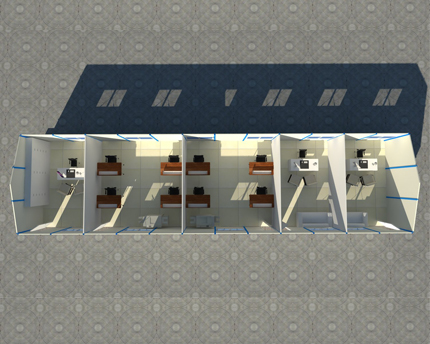

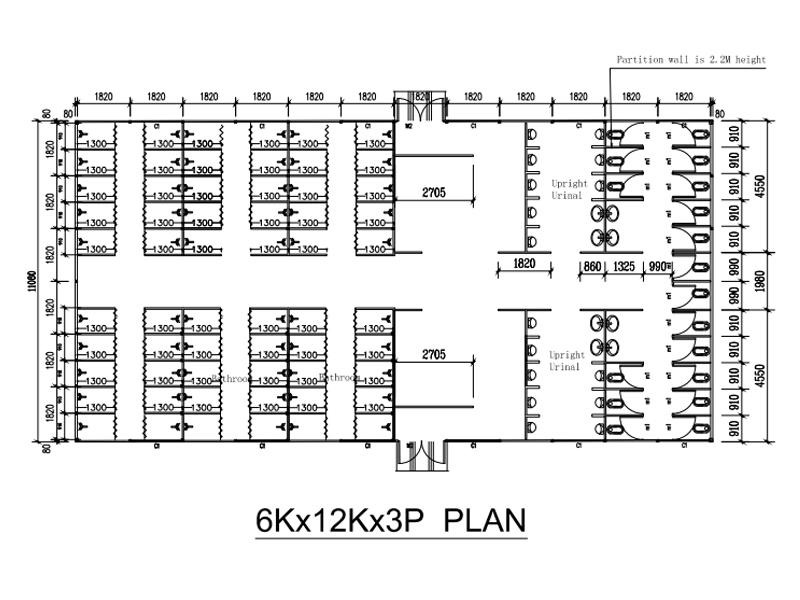

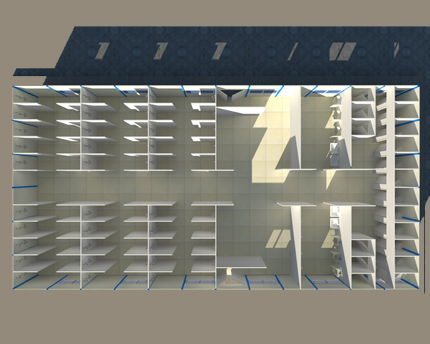

K LABOR CAMP All the building in this prefab labor camp is K house design, which characteristic for the fast installation building with cheap price and can be assembled and disassemble 6 times. Because for these advantage,are widely used in the labor/worker camp and construction sites. 1X40HQ can load 280-320 square meter. Inside worker accommodation camp, have the prefab dormitory building, prefab canteen building, prefab office building, prefab shower room/toilet building and clinic. All these building designs are customized, very flexible.

Main materials: Steel structure: "C" section steel+ angle steel Wall and roof:50/75/100mm EPS/ROCK WOOL /PU sandwich panel Window: Aluminum sliding window/ plastic window Door: Sandwich panel door/ steel door Floor: cement board/ plywood board

بازدید : 42 [ پنجشنبه 30 مرداد 1399 ] [ پنجشنبه 30 مرداد 1399 ]

[ cleanroomffu ]

The hospital’s clean room is a biological clean room. The hospital’s biological clean room is airtight. After reasonable zoning, process design, air purification and other construction links, it can effectively reduce cross-infection and control the spread of bacteria and viruses in the air. During the construction, Wiskind Cleanroom discovered that the biological clean rooms of many hospitals have hidden dangers of congenital deficiencies, and there are many social problems such as concept, plan, design, equipment configuration, construction technology and so on.

1. Can the positive pressure clean operating room operate on patients infected by this epidemic? The main route of transmission of this epidemic is droplets attacking the respiratory system and mucous membranes through the air. At the same time, droplets are also contaminated on the surface of objects and are transmitted through human contact . The transmission routes are multi-directional. It is recommended that such infected patients should be operated in a negative pressure operating room. However, if there is no negative pressure operating room in the operating department of some hospitals, and the patient must perform the operation, the operation should be arranged in an operating room with a separate area as much as possible.

2. If an operation is performed on a severely infectious patient in a positive pressure clean operating room, how to disinfect the purification unit system? After the positive pressure clean operating room is operated on patients with severe infectious diseases, the disinfection requirements are the same as those of the negative pressure operating room. In addition to the operating room to cleanroom wall panels , roof, floor, cleanroom door, outlet and all indoor facilities and equipment to conduct a comprehensive, thorough, serious, no dead outside cleaning disinfection, but also carefully clean up all the gaps, strict disinfection.

In terms of purifying the air system, the professional team of professionals should replace the return air filter, the circulating unit filter, the air supply port (or air supply ceiling) high-efficiency filter, and the exhaust system filter under the premise of self-protection. , The replaced filter should also be disinfected, sealed and then disinfected.

Carry out careful and thorough disinfection of air ducts participating in circulation and discharge and fresh air supply ducts without check valves. It is best to use atomized hydrogen peroxide for air duct disinfection.

It is also necessary to carry out disinfection and sterilization measures for the participating unit systems, which mainly refer to the circulation unit, the inside and outside of the exhaust fan unit, and the computer room.

3. What is the main difference between a positive pressure clean operating room and a negative pressure operating room? The positive pressure clean operating room is an operating room with clean levels (level I , II , III , IV ). Its air system is composed of treated clean fresh air + circulating clean air with different air changes + exhaust air , That is, there is fresh air, circulating air, and exhaust air. The starting sequence of the fan should be fresh air, circulation and exhaust air. The volume of fresh air sent to the operating room is greater than the volume of exhaust air. The relative pressure in the operating room is greater than the pressure in the adjacent room. Its protection objects are mainly surgical patients. Because the exhaust vent of the clean operating room is mostly designed on the top of the operating room, the exhaust fan is a single fan system, and the exhaust air does not need to be equipped with a high-efficiency filter, but only a junior high-efficiency filter.

The negative pressure operating room is generally an operating room with no cleanliness level. Its air system is composed of treated clean fresh air + exhaust air, that is, direct delivery and direct exhaust. The starting sequence of the fan should be exhaust air, fresh air, and the fresh air volume sent to the room is less than the exhaust air volume. The relative pressure in the operating room is less than the relative pressure in the adjacent room. Its protection objects are mainly medical staff and the surrounding environment. The air outlet of the negative pressure operating room should be located at the lower end of the side wall of the operating room close to the patient's head and on the side of the top anesthesia work area. The exhaust fan system is a double fan. The exhaust air must be equipped with a high-efficiency filter.

4. How can we know that the clean room and related controlled environment of our hospital are safe during use? The main purpose is to be "controllable" and "knowable" for the key parameters designed in accordance with the relevant national standards for the clean room and related controlled environment of our hospital. That is to say, the use process of the clean room and related controlled environment in our hospital is a dynamic process (infection also occurs in the dynamic process), and various parameters of the environment are realized in the dynamic process. Real-time monitoring and management of parameters can realize whether the environment is safe or not. However, the clean rooms and related controlled environments of most hospitals in our country do not have real-time management configurations, so it is basically impossible to know whether our own clean rooms and related controlled environments are safe. This is a shortcoming in the construction and use of clean rooms and related controlled environments in our national hospitals.

Some hospitals now install pressure display devices in clean rooms, so that you can know whether the air in the clean room is leaking and the general situation of organized air flow. However, the pressure of many hospitals shows that the values displayed by the facilities are ridiculously deviated, which can mislead us.

At present, the method of bacterial sampling and culture readings in clean rooms and related controlled environments in hospitals can most directly reflect the safety status of hospital clean rooms and related controlled environments. Although there are many indicators for the safety factor of hospital clean rooms and related controlled environments, they are comprehensive, but the bacteria indicators are the most critical and important. However, it takes a long time for bacterial samples to be cultured and the feedback of safety information is delayed. If it is in an extraordinary period of the fight against the epidemic, it is recommended to increase the time density of bacterial sampling and analysis in key areas.

5. If the hospital is to rebuild some negative pressure isolation wards in the existing buildings, what aspects should be paid attention to? MasterCard believes that the most critical issue in the construction of negative pressure isolation wards in hospitals is the concept. Although the negative pressure isolation ward of the hospital and the clean operating room, ICU , supply room, liquid distribution center, laboratory, etc. are all controlled environments, the negative pressure isolation ward is not a clean room and does not require expensive air purification systems.

Negative pressure isolation wards are mainly used to treat patients with respiratory infections. The principles that must be followed when designing are to control the air transmission of the virus, cut off the air transmission chain of the virus, and simultaneously implement physical separation and air isolation of the source of infection. When designing, we must insist on: zone prevention and control, layer by layer check; process safety, reasonable and convenient; isolate the source of disease and cut off transmission.

It is best to use a dual-channel mode for partitioning, which can be divided into clean area, semi-contaminated area (also regarded as a buffer zone), ward area (contaminated area), and other auxiliary areas. Each area can be an independent area, and each area is divided or connected in the form of a buffer.

The flow of people and things must be "buffered." Each area requires functional satisfaction and complete equipment. All items that need to be removed from the contaminated area and semi-contaminated area, especially patient excrement and medical waste, shall have special areas for disinfection, sorting and packaging, and re-sterilization.

The air isolation system uses an organized gas flow pattern. The air supply in polluted and semi-polluted areas adopts full delivery and full exhaust. The fresh air should be treated, with initial, medium and sub-high efficiency filter sections. The exhaust fan unit should be equipped with dual fans, one fan is used and one is prepared, and the standby fan can be quickly started. The external discharge of the exhaust system must pass through a high-efficiency filter section, and a qualified and effective check valve must be installed. The exhaust vent must have a certain height, and the discharge direction must be reasonable.

Arrangement of air supply and exhaust vents: The air supply vent of the isolation ward should be located at the top of the side where medical staff enter the operation area of the ward, and the exhaust vent should be located on the underside of the wall near the patient's head in the bed. The air outlet for the buffer zone should be located at the lower end of the wall near the isolation ward. The air outlets of the clean area are arranged according to the position of the air-conditioning outlets of the normal normal office area. The temperature of the isolation ward should be set not less than 22 ℃, and can be moderately higher if possible.

Pressure gradient setting: For the design of a completely independent indoor negative pressure isolation ward, it is best to have a positive pressure buffer channel at the beginning of entering the area, and use positive pressure to protect and separate other areas. The clean area is normal pressure Zone, the buffer zone starts as a negative pressure zone. The isolation ward and the sewage treatment and disinfection room are the main negative pressure area, and the pressure gradient is the highest negative pressure in the entire area.

The number of air changes is set to 12 , which does not mean that fresh air must be sent in 12 times and the air volume must be discharged 12 times. The American standard is also 12 times of air change, but they only send in fresh air for 2-4 times and discharge 12 times of air. The large amount of 8-10 times air volume is the air volume leaked from other areas. The door of the negative pressure isolation ward does not need an airtight door, and it is normal for other areas to vent into the air.

In addition, the operating parameters of the negative pressure isolation ward should be set to remote real-time monitoring mode. The isolation ward should be equipped with high-definition video screen equipment to remotely observe the patient's condition in real time. The sewage discharge from the negative pressure isolation ward is not allowed to be directly discharged to the corresponding sewage discharge system of the hospital. The sewage must be equipped with disinfection equipment and can be discharged after disinfection.

The use of negative pressure isolation wards to treat severely infected patients is an effective means to control the source of infection and cut off the air transmission chain. The hardware construction is one aspect, and the other aspect: use and management are equally important.

[ جمعه 24 مرداد 1399 ] [ جمعه 24 مرداد 1399 ]

[ cleanroomffu ]

UV germicidal technology has existed for decades, and it is a proven and efficient broad-spectrum sterilization technology. However, in the past decades, the styles and types of commercial and household UV devices on the market have changed very little. So, the styles of many UV sterilization products are relatively old. This year, the development of ultraviolet disinfection equipment ushered in an opportunity. Due to the influence of the COVID virus, UV disinfection products have developed explosively in 2020. Whether it is the market demand or recognition, or the style and quantity of newly developed products, are growing rapidly.

FuturizedUV Disinfection Robot Due to the epidemic, there is a huge demand for disinfection in a variety of public and commercial places, including hospitals, hotels, shopping malls, and public vehicles. But high concentrations of disinfectants and ultraviolet rays are usually not suitable for exposure to common areas with people directly. So, some technology companies that specialize in robotics and AI technology combine UV disinfection with robotics to replace manual disinfection of large sites. According to statistics, in a short period of half a year from the beginning of this year to now, dozens of companies around the world have developed hundreds of ultraviolet disinfection robots. These futuristic robots can not only replace people to perform high-intensity ultraviolet disinfection without damage, advanced AI technology can also help them automatically plan work, design itinerant routes, and do disinfection while there is no one.

User-friendly Home UV Sterilizer All kinds of household UV sterilizers are the common products in the market, but the upgrading of these products has been slow in previous years. In a long time, the more common in the market is tableware disinfection cabinet, UV disinfection cabinet, and so on. Their styles and function are relatively ancient and rough. Some of the products even look like old lab devices. In recent years, some new changes have taken place in the products on the market. And these changes have been exacerbated by surging market demand due to the influence of the COVID virus this year. According to incomplete statistics, in the past few months, the styles of newly listed disinfection products have increased by more than 300%, and most of them were developed and put into production in the last two months. For example, the styles of portable UVC sterilizer wand sold on Amazon have multiplied several times in a month, and the shapes are more fashionable and novel. In addition, due to the impact of the COVID epidemic, the scope of application of newly listed disinfection products is also rapidly subdivided and expanded. Besides the common baby bottle sterilizer dryer, desktop UV sterilizer box, and other products, there are also many products in new fields such as home UV mask sterilizers, UV makeup brush sanitizer and so on. Of course, in addition to being better-looking and more comprehensive in scope, functional design is also becoming more user-friendly.

The COVID epidemic has brought a strong driving force to the market development of UV sterilizer products. Some experts predict that even after the epidemic, the development and market growth of UV products will continue for a long time.

[ پنجشنبه 16 مرداد 1399 ] [ پنجشنبه 16 مرداد 1399 ]

[ cleanroomffu ]

Through research over the past few months, many scientists from all over the world have proved that UV can effectively kill the COVID19. As recently as July, researchers from Columbia University said they had solid evidence that UV could effectively kill coronaviruses, including COVID19, H1N1 flu viruses etc. Scientists believe that this study provides a new weapon and theoretical basis for the fight against this epidemic.

Before this, many innovative companies invested their technological power in the innovative R&D of ultraviolet products ahead of time because of the prediction of the market and tech. Until now, there have been a number of new UV products on the market, and most of them have got positive feedback from the market.

Masks are important protective equipment that has attracted much attention in this epidemic. Recently, several new UV sterilization masks have displayed on some well-known online crowdfunding platforms. Tech companies combined UVC germicidal light into traditional filter masks to develop new products with disinfection and self-purification functions. These UV germicidal masks are popular with consumers while they just hit the market, raising millions of dollars each on crowdfunding platforms in just over a dozen days.

UV makeup brush sanitizer is also a kind of new product that is very popular in the market at present. Compared with the ultraviolet disinfection mask, the UV tool sterilizer box dryer is a micro-innovation of products by professional disinfector manufacturers. Combine the beautiful desktop storage box with UVC disinfection technology, with sufficient disinfection room, beautiful looks, unique germicidal drying function and clean storage function. The launch of this product not only meets the needs of disinfecting small daily items during the epidemic, but also meets the daily needs of many people to store clean items. So, this product has been included in the purchase list by many professional buyers as soon as it was launched.

Not only these, but also many innovative products using ultraviolet disinfection technology, such as UV air cleaner specializing in disinfection air, Smart elevator UV cleaner Light with automatic cleaning function, and so on, have become the most popular product choices in the current market. And it is believed that in the coming future, there will soon be more innovative UV devices recognized by consumers on the market.

[ پنجشنبه 16 مرداد 1399 ] [ پنجشنبه 16 مرداد 1399 ]

[ cleanroomffu ]

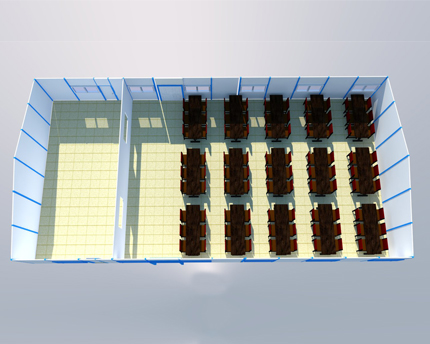

With the development of computers, microelectronics and information technology, the rapid development of the electronics manufacturing industry has been promoted, and the development of clean room technology has also been promoted. At the same time, higher requirements have been put forward for the design of modular clean rooms. The clean room design of the electronics manufacturing industry is a comprehensive technology.

Only by fully understanding the design characteristics of the dust-free workshop of the electronics manufacturing industry and achieving reasonable design, can the product defect rate of the electronics manufacturing industry be reduced and production efficiency improved.

Features of electronic clean room The cleanliness level is required to be high. The air volume, temperature, humidity, pressure difference, and equipment exhaust are controlled on demand. The illuminance and clean room section wind speed are controlled according to design or specifications. In addition, electronic clean rooms have extremely strict requirements for static electricity.

Among them, the requirements for humidity are strict, because static electricity is easily generated in an excessively dry plant, which can cause damage to the CMOS integration.

Generally speaking, the temperature of the electronic workshop should be controlled at about 22℃, and the relative humidity should be controlled between 50-60% (special clean workshops have relevant temperature and humidity regulations). At this time, static electricity can be effectively eliminated and people feel comfortable.